July 30, 2022 15:13 by

admin

adminWe, Ti anode fabricators Pvt. Ltd., is familiar in manufacturing and supplying of MMO & Platinum plated Titanium and Niobium anodes for Impressed Current Cathodic Protection (ICCP).

Platinized Nickel Rod anodes are planned with explicit platinum material (Pt.) which makes the anodes correspondingly stable for a long time. Tiaano designs and production platinised Nickel Rod anodes with various aspects and plating thicknesses. Tiaano have the factory to do platinum plating 0.5 micron to 20 micron thick by the course of Electro affidavit.

Nickel is slow to oxidise at room temperature and hence it is considered to be naturally corrosion resistant. High-performance nickel alloys are also resistant to reducing media, aggressive chemicals and seawater. Corrosion-resistance properties vary depending on the Grade chosen for your pipes.

Long life, correspondingly steady and effortlessly created into any shape: When utilized in the plating system, aspect of the lead anodes are changing because of the deficiency of the lead oxide which is framed on the anode during activity - it leads surface region is getting imploded. Likewise bigger lead anodes can extend under their own weight. While titanium anodes are correspondingly steady all through their working life and can without much of a stretch be fabricated, even in complex shapes and lengths, up to 4m. Thusly, formed anodes can be fabricated precisely to permit steady plating to little resilience’s, frequently making a further sharpening step pointless.

Energy reserve funds with moulded anodes and little anode/cathode distances: Small terminal holes lessen electrical obstruction misfortunes in the plating shower and produce energy investment funds. On account of lead anodes, which can't be framed as precisely as a lattice, opposition misfortunes bring about shower warming, requiring further energy for cooling. In this manner, platinised titanium anodes can give energy reserve funds both in warming and cooling which, thusly, permits the plating science to be more straightforward to oversee and keep up with.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

3f25f0bf-3691-4260-a18e-661a234d0a33|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 27, 2022 17:29 by

admin

admin

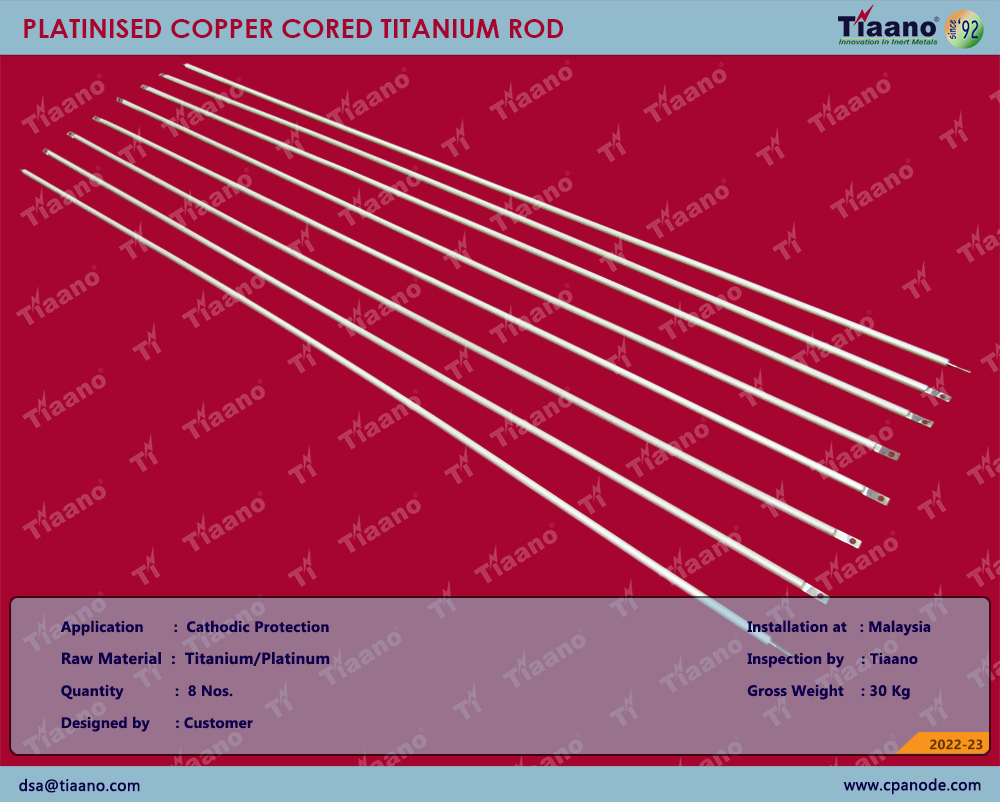

PLATINISED COPPER CORED TITANIUM ROD

Platinized titanium anodes are extensively used in electrolytic processes. They have successfully replaced lead anodes in electroplating applications due to their lower consumption, dimensional accuracy, ability to form precise deposit thicknesses on desired geometric shapes, predictable plating chemistry and ease of maintenance. These anodes can be designed and formed with various geometries based upon the parts to be electroplated.

Platinum on titanium anodes are highly preferred anodes for electrodeposition of copper, chromium, platinum, nickel, palladium and gold.

Platinized titanium anode by adopting thermal decomposition process to get a dense wear-resistant layer of platinum coating. The anode surface is modified to improve adhesion of platinum and to significantly improve uniformity of coating thickness, also reduce the coating porosity imparting greater acid resistance to the anode. This platinum coated titanium anode can be fabricated into bar, rod, sheet, mesh and other customized shape to meet your special needs.

Because of its high conductivity and low consumption rate, Platinum is an excellent anode material. Due to its high cost, Platinum is made practical for use by electroplating a thin layer over a high corrosion resistance substrate. Since Titanium, Niobium and Tantalum substrates have the ability to form an insulating oxide film under anodic conditions, they are commonly used as anode in ICCP (impressed current cathodic protection anode). Among them, Titanium is less expensive; however, it has a much lower breakdown potential than Niobium or Tantalum. The titanium oxide breaks down at anodic potentials in the 12 V range.

Advantages of platinized titanium anodes

Low consumption rate and high current density

Voltages in excess of 10 Volts will result in severe pitting of the titanium core causing premature failure

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

8730cea2-7309-4f2f-be20-436e3dc27e35|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 21, 2022 18:09 by

admin

admin

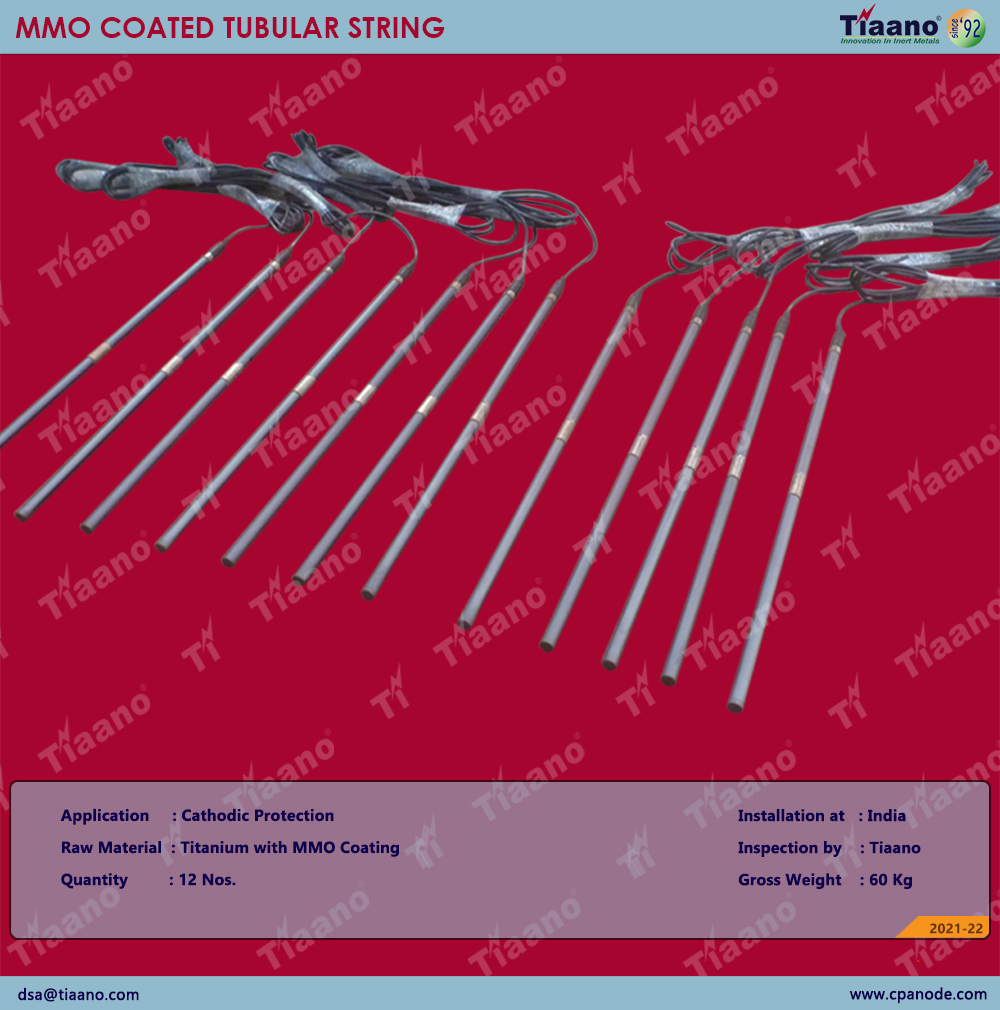

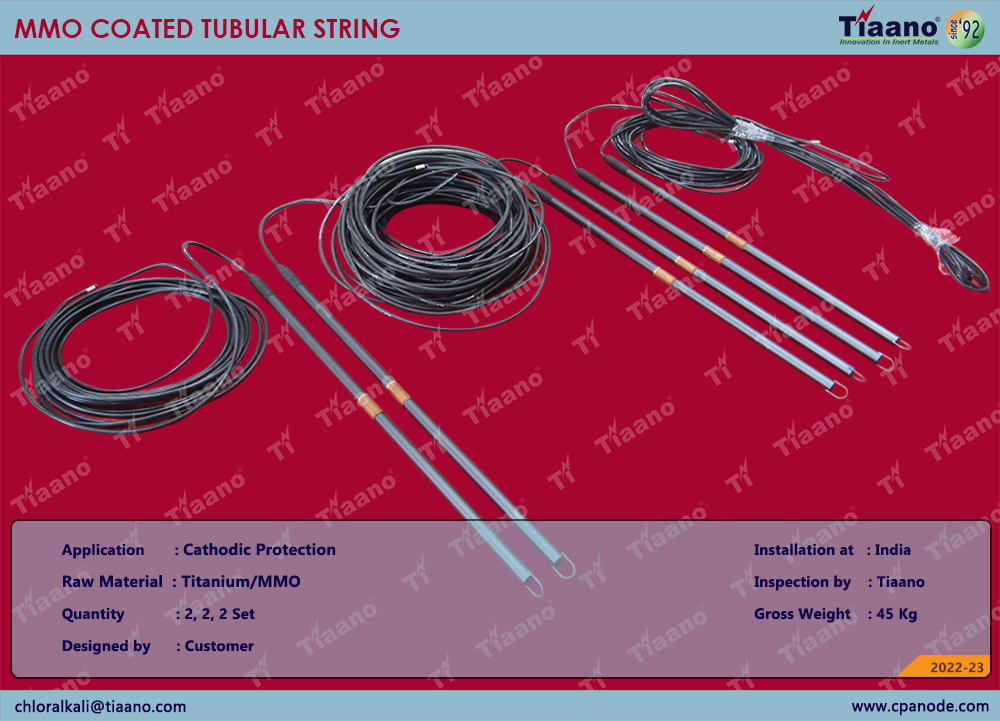

MMO Coated Tubular String for Cathodic Protection

We Tiaano do fabrication & supply of MMO Titanium tubular anodes by using titanium seamless tube and coated with platinum group precious metal mixed oxide coating. Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements

Mixed Metal Oxide Coated Titanium anode design for the demands of deep anode beds, shallow beds and the earth’s natural waters. MMO Tubular anodes are dimensionally stable anodes which remain constant throughout all of the anode life, thus providing a constant performance with a low resistivity MMO Titanium tubular anodes are a titanium tube base with a mixed metal oxide conductive coating and itself an excellent electronic conductor.

The design life of the anode varies with operating current in a variety of applications from seawater to soil. Tubular Anodes are available in a number of diameters, lengths, current carrying capacities and life ratings.

MMO tubular anode can be in single or in string, it is generally adopting titanium tubular as substrates and coated with a mixed metal oxide catalyst.

Mixed metal oxide based electrocatalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current..

Benefits of MMO Coated Tubular String:

· Lightweight/Durable

· High current output

· Low cost

· Dimensionally stable

· High cost performance

The specification of the below displayed MMO Coated Titanium Tubular String Anode

|

Material

|

Titanium

|

|

Coating

|

MMO

|

|

Country of origin

|

India

|

|

Thickness

|

0.9 mm

|

|

OD

|

25.4 mm

|

|

Length

|

500 mm

|

Cathodic protection is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. A simple method of protection connects the metal to be protected to a more easily corroded "sacrificial metal" to act as the anode.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

c2437e51-369e-48b1-b64a-29a4318cedb5|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 15, 2022 12:42 by

admin

adminCorrosion is naturally a destructive process that occurs when some metals are exposed to the environment and occurs when reaction between air, moisture and the metal gives rise. It commonly occurs in iron-based metals, steels etc. There are different methods to prevent and control corrosion. One of the best known method is Cathodic Protection.

Cathodic protection is one of the main technique to prevent corrosion. Cathodic protection is of two types they are Impressed Current Cathodic Protection (ICCP) and Galvanic Protection also known as DCCP. Cathodic protection systems protects a wide range of metallic structures in various environments.

Titanium is highly resistant to chemical attack and has the most elevated solidarity to weight proportion of any metal. These unique properties make Titanium reasonable for a large number of utilizations. It's firmness to weight proportion as steel is like steel meaning it can be used as a substitute where weight is an important consideration.

Follow us on:

Pinterest, Instagram, Facebook, Twitter

69abe517-c1d9-4374-b3bc-b4051d1c95a1|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 16, 2022 11:40 by

admin

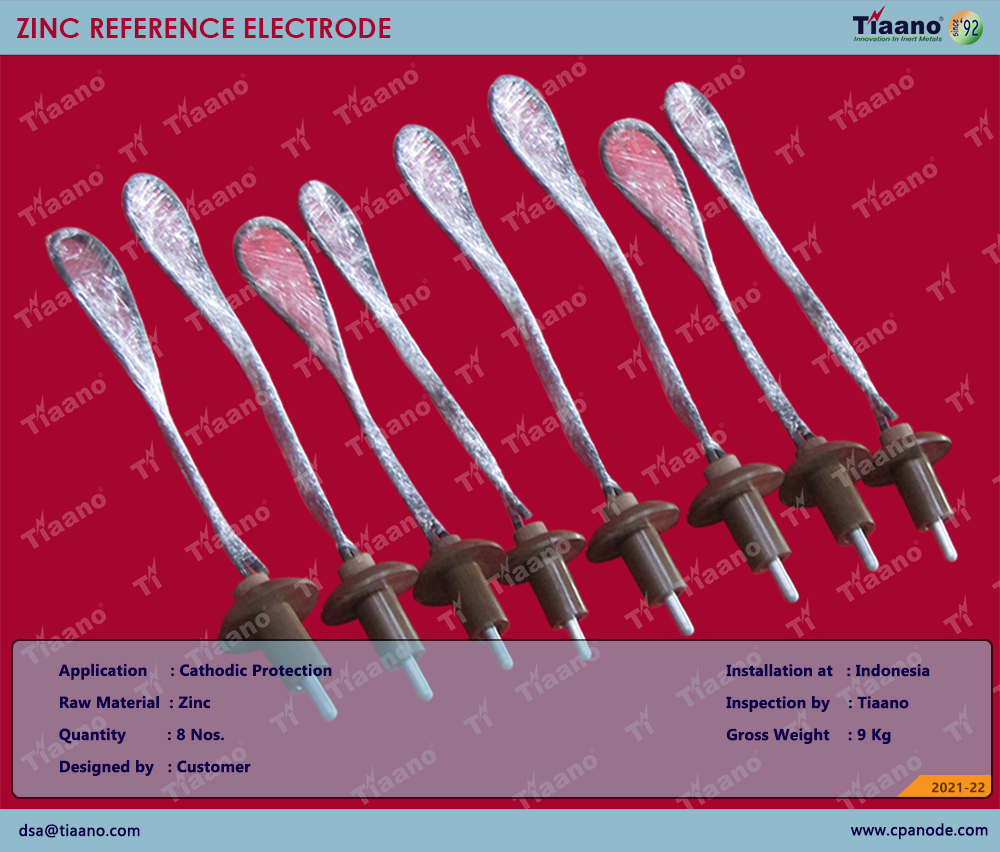

adminZinc Reference electrodes are generally implemented for the purpose of monitoring the anode in cathodic protection of buried or immersed metallic structures. It is made of high-purity Zinc alloy, ensuring accuracy and stability of potential measurements. The electrode frame is made of stainless steel, coated carbon steel or Rubber. The electrode can be designed to fix in the structure. By means of specifically designed supports.

These Zinc Reference Electrode implements a major usage in the cathodic protection System. Zinc reference Electrode are in different shapes like disc, rod and strip with different dimension, which is also installed in the Heat exchanger to monitor the current supply of Cantilever anodes.

Follow us on:

Pinterest, Instagram, Facebook, Twitter

9d93ceaa-27d3-4479-977f-3e9901facd8e|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 16, 2022 11:20 by

admin

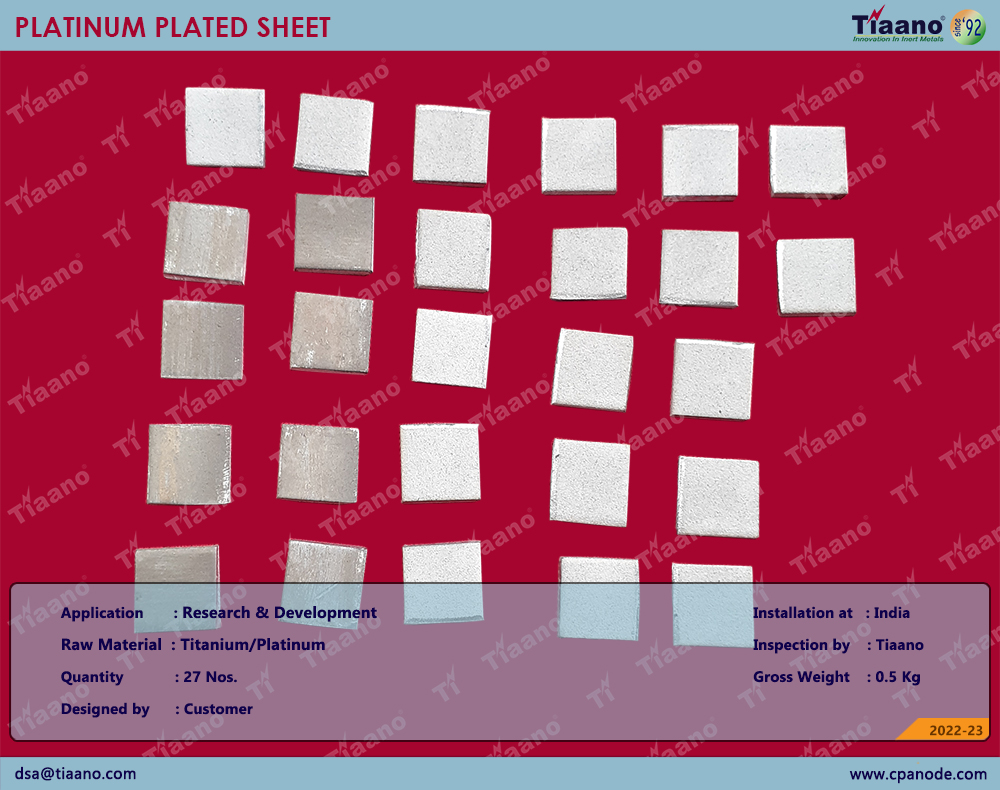

adminPlatinum is an excellent catalyst because of its high conductivity and low utilization rate. Platinum deposition made by electroplating strategy over a high corrosion resistance substrate (Titanium). Since Titanium substrate is having non-destructive nature structure by protecting oxide film by platinum plantings.

Platinized cantilever anode is utilized for safeguarding pipeline internals, pull and condenser box inner for a long time and more by applying DC current with transformer rectifier. Ordinarily titanium is notable for its high protection from erosion both water and chemical media but titanium is the poor electricity conductor. So we use platinum/MMO plating/coating to expand the conductivity.

Advantages:

- Low consumption rate that conserves precious platinum.

- Favourable dimensional stability.

- Corrosion resistance ensures durability with easy maintainability.

- Light weight, as well as favourable current distribution in electroplating.

Tiaano manufacturing and supplying various anodes for cathodic production based on titanium, niobium and other exotic metals. We produce a wide variety of standard and customized anode shapes to maximize your benefit.

0e238642-7354-4b0a-a5f0-5c7cc783686f|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 9, 2022 10:36 by

admin

adminImpressed Current Cathodic Protection frameworks are a definitive answer for all erosion issues to safeguard the metallic design for long time and are perceived as a better option than conciliatory anode frameworks which require successive substitution. Intrigued current cathodic security frameworks are liked by transport proprietors since they decrease fuel cost and support.

MMO/Platinised Disc, Elliptical and Strip Anodes are grown explicitly for security of Dam and Navigation lock entryways. Since our disc, elliptical & strip anodes are intended to work in new, saline and seawater conditions - utilized in other appropriate applications incorporates marine designs, water tanks and vessels. With a discretionary essential seal spacer gasket, it very well may be utilized within pipes, siphons, water tanks or other bended surfaces as well.

Disc anodes can be installed in dividers of boat bodies, condenser/water box, siphon inward/outside attractions and release to safeguard for longer years. It will be protected with rubber treated form to safeguard from disintegration. While utilizing MMO covered rubber treated plate anode to safeguard the boat structure from ocean water consumption, outside flow are applied to change over high expected anodic locales on a boat frames to low-likely cathodic destinations This ensures that ship hull surface is protected from corrosion.

Follow us on:

Pinterest, Instagram, Facebook, Twitter

03fe1031-d2ae-4907-8009-b2e8cb800944|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 7, 2022 09:39 by

admin

adminPlatinum is preferred on an anode's outer surface because it is highly resistant to corrosion and can ensure current flow in most electrolyte media without leading to the formation of an insulating layer on itself.

The product is made up of titanium and coated with platinum to withstand corrosion, where titanium and platinum has good resistant. Titanium has less dense and strong durability than other metals and can withstand high temperature. Platinum is highly non-reactive and cannot be rusted easily because it has no iron on it.

The product we supplied is used for Research and development(R&D) that includes activities where companies undertake to innovate and introduce new products.

Advantages of Platinised Titanium Anode:-

- Low weight

- Energy saving potential,

- High electrical conductivity

- High dimensional stability and load resistance.

- High corrosion resistance

For more details visit these links:

www.cpanode.com,www.tiaanostore.in,www.tiaano.com

Follow us on:

Pinterest, Instagram, Facebook, Twitter

a4551b99-aa55-4bd6-a2a8-1acb8a7ff337|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 7, 2022 09:27 by

admin

adminWe, Ti anode fabricators Pvt. Ltd.,is familiar in manufacturing and supplying of MMO & Platinum plated Titanium and Niobium anodes for Impressed Current Cathodic Protection (ICCP). According to the customer’s requirement we manufacture the anodes from copper cored titanium and copper cored niobium too.

MMO anodes have imperceptibly low wear rates and are often referred to as Dimensionally Stable Anodes as they do not change geometry over time. MMO anodes are quickly becoming the most popular impressed current anode. MMO coated tubular string anode are used to protect the pipe lines which is installed horizontal bed as well as vertical deep well with multi string /single string based on several design and field condition factors including current distribution requirements for different application like Sea water, brackish water, sand etc.,

For more details visit these links:

www.cpanode.com,www.tiaanostore.in,www.tiaano.com

Follow us on:

Pinterest, Instagram, Facebook, Twitter

2b311e94-a275-470c-a476-43531f62af63|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

April 29, 2022 14:44 by

admin

adminCathodic protection (CP) is a technique used to control the corrosion of a metal surface by passing positive connection in the anodes side and negative connection in the cathodes side.

Platinized cantilever anode is used for protecting pipeline internals, suction and condenser box internal for 30 years and more by applying DC current from rectifier. Cantilever anode is coated with platinum or MMO (mixed metal oxide). The cathode will be protected and could be monitor by the reference electrodes.

Platinized titanium rods are usually used in cantilever anode. Normally titanium is well known for its high resistance to corrosion both water and chemical media but titanium is the poor electricity conductor. So we use platinum/ MMO plating/ Coating to increase the conductivity.

Advantages of Platinum coating:

• Low consumption rate that conserves precious platinum.

• Corrosion resistance ensures durability with easy maintainability.

• Light weight, as well as favorable current distribution in electroplating.

• Favorable dimensional stability.

Recently supplied platinum plated cantilever for our Indonesia client

For more details visit these links:

www.cpanode.com,www.tiaanostore.in,www.tiaano.com

Follow us on:

Pinterest, Instagram, Facebook, Twitter

b70602e6-4fd7-4465-99f7-a6d3983e4910|0|.0|27604f05-86ad-47ef-9e05-950bb762570c