June 2, 2023 09:48 by

admin

adminTi Anode Fabricators Pvt Ltd., manufactures CPCC Canister Anode with their in-house facilities in India, for impressed current cathodic protection application. Using following alternative anode combinations are been supplied based on the customer’s interest. Titanium expanded mesh with Ti’s MMO coating. Titanium wire with Ti’s MMO coating. Titanium expanded mesh with Ti’s Platinum plating. Titanium wire with Ti’s Platinum plating. Niobium wire with Ti’s MMO coating. Niobium wire with Ti’s Platinum plating.

Application:

· Shallow vertical and horizontal surface ground beds.

· Underground storage tanks.

· Above ground storage tanks.

· Pipelines.

Advantages over Silicon - Iron anodes:

Twice the life, Unbreakable, Lighter weight, Easier to install, Narrower trench, Easy to centralize, Reduce excavation and drilling cost.

Material of Construction:

Canister: Galvanized steel tube

Substrate: Titanium, ASTM B 265 or 348 Gr.1

Niobium, ASTM B

Catalyst: MMO or Pt

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

efb8e614-bf25-4c95-a061-4115fa554e30|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

May 15, 2023 13:56 by

admin

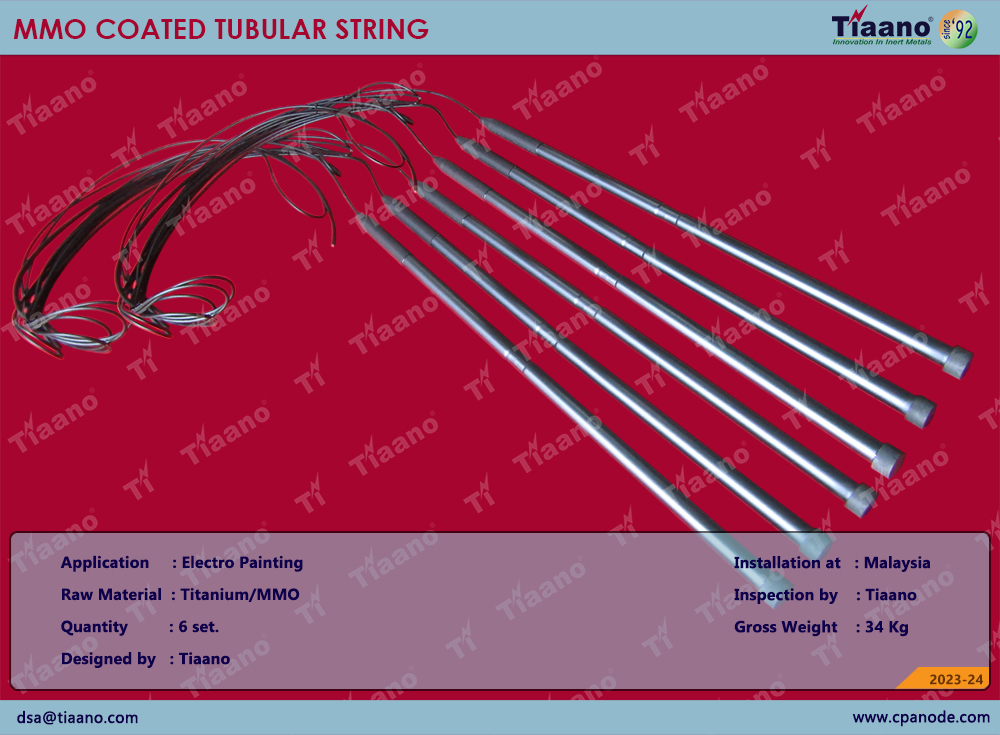

adminTitanium tubular anodes are manufactured using titanium seamless tube and coated with platinum group precious metal mixed oxide coating.

Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements.

Mixed metal oxide based electro catalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current.

Mixed Metal Oxide anodes are typically rated for a given output and life, for example 5 amps at 20 years. Within the normal range of current discharge for MMO anodes, this relationship is linear. The same 5 amp anode rated for 20 years of service would provide 40 years if only operated at 2.5 amps.

Benefits of MMO Coated Tubular String:

· Lightweight/Durable

· High current output

· Low cost

· Dimensionally stable

· High cost performance

7df314f3-64e4-4562-bb2f-f18291dd43af|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

February 2, 2023 11:30 by

admin

adminWe, Ti Anode Fabricators Pvt. Ltd., developed an extremely strong and electrically low resistance centre crimp connection, which ensures the lowest possible electrical resistance (less than 1.0 Milli Ohm) between the cables and anode tube. The Platinum group Mixed Metal Oxide coating is a crystalline electrically conductive coating that activates and enables a titanium substrate to function as an anode. Whether operating in fresh water, seawater, soil, or mud. MMO Coatings are extremely stable even in very low pH environments.

MMO titanium tubular anodes are coated with mixed metal oxide that has an extremely low consumption rate measured in milligrams per year. Unlike other types of anodes the consumption rate of MMO anode is negligible with the dimensions of the anode element remaining virtually unchanged during the operational service life of the anode. As a result, the power required to impress current will remain the same.

Cathodic protection system is a technique used to control a corrosion of a metal surface by making it the cathodic side of an electrochemical cell. Cathodic protection is an old and effective system that prevents forming rust in metal and helps in corrosion resistant. Corrosion can be prevented by eliminating the oxygen or the positively charged hydrogen ions.

|

Material

|

MMO Titanium

|

|

Usage/Application

|

Cathodic Protection ICCP

|

|

Brand

|

Tiaano

|

|

Thickness

|

Wall Thickness 0.9 mm

|

|

Country of Origin

|

Made in India

|

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

f06eaddb-ce40-467c-bfc0-07ba1fec3821|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

September 19, 2022 14:39 by

admin

adminTitanium tubular anodes are manufactured using titanium seamless tube and coated with platinum group precious metal mixed oxide coating. Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements

Mixed Metal Oxide Coated Titanium anode design for the demands of deep anode beds, shallow beds and the earth’s natural waters. MMO Tubular anodes are dimensionally stable anodes which remain constant throughout all of the anode life, thus providing a constant performance with a low resistivity

MMO Titanium tubular anodes are a titanium tube base with a mixed metal oxide conductive coating and itself an excellent electronic conductor.

The design life of the anode varies with operating current in a variety of applications from seawater to soil. Tubular Anodes are available in a number of diameters, lengths, current carrying capacities and life ratings.

MMO tubular anode can be in single or in string, it is generally adopting titanium tubular as substrates and coated with a mixed metal oxide catalyst.

Mixed metal oxide based electro catalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current.

Mixed Metal Oxide anodes are typically rated for a given output and life, for example 5 amps at 20 years. Within the normal range of current discharge for MMO anodes, this relationship is linear. The same 5 amp anode rated for 20 years of service would provide 40 years if only operated at 2.5 amps.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

cd06c6dc-a550-4319-8b3a-888c05a953e6|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 1, 2022 15:57 by

admin

adminPlatinized titanium and MMO coated titanium rod anodes are to be designed & manufactured by Ti Anode Fabricators Pvt Ltd, Chennai, India. Application: Deep & conventional ground beds. Jetties in fresh and brackish.

Substrate: Solid Titanium and Niobium & Copper cored Ti. Catalyst for surface Coating: Platinum Mixed Metasalt-water electrolytes. Water tanks. Lock Gates. Intake Screens. Marine application Oxide

Platinized Titanium and Niobium probe / cantilever type anodes are also available for use in Internal ICCP of process vessels such as pipes, condenser water boxes and heat exchangers where the interior is difficult to access and its space limited. Such anodes are often mounted through the vessel shell, with the anode part of the probe extending into the vessel, and wire connections made to the probe on the exterior of the vessel.

Tiaano offer Platinised Titanium and Niobium cantilever (probe) anodes for this application (medium seawater, fresh water and brackish water) Also Tiaano offer platinized Rods and Tubes suitable for cantilevers (probes).

The primary use of platinized titanium anodes is in the field of Cathodic Protection. The anodes are used in structures buried in soil and the steel exposed to marine environments such as oil and gas producing platforms, ships, oil well casings and jetties.

Platinized Titanium Anodes synergistically combine the favourable electrochemical features of platinum (Pt) with the corrosion resistance and other characteristics of titanium. They are anodes normally produced by the electrochemical deposition of a very thin layer of platinum metal onto a titanium substrate. These anodes operate as inert anodes with high durability and are preferred because they remain insoluble in common electrolytes.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

1c06246a-337e-467d-a062-b988590ae303|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 30, 2022 15:13 by

admin

adminWe, Ti anode fabricators Pvt. Ltd., is familiar in manufacturing and supplying of MMO & Platinum plated Titanium and Niobium anodes for Impressed Current Cathodic Protection (ICCP).

Platinized Nickel Rod anodes are planned with explicit platinum material (Pt.) which makes the anodes correspondingly stable for a long time. Tiaano designs and production platinised Nickel Rod anodes with various aspects and plating thicknesses. Tiaano have the factory to do platinum plating 0.5 micron to 20 micron thick by the course of Electro affidavit.

Nickel is slow to oxidise at room temperature and hence it is considered to be naturally corrosion resistant. High-performance nickel alloys are also resistant to reducing media, aggressive chemicals and seawater. Corrosion-resistance properties vary depending on the Grade chosen for your pipes.

Long life, correspondingly steady and effortlessly created into any shape: When utilized in the plating system, aspect of the lead anodes are changing because of the deficiency of the lead oxide which is framed on the anode during activity - it leads surface region is getting imploded. Likewise bigger lead anodes can extend under their own weight. While titanium anodes are correspondingly steady all through their working life and can without much of a stretch be fabricated, even in complex shapes and lengths, up to 4m. Thusly, formed anodes can be fabricated precisely to permit steady plating to little resilience’s, frequently making a further sharpening step pointless.

Energy reserve funds with moulded anodes and little anode/cathode distances: Small terminal holes lessen electrical obstruction misfortunes in the plating shower and produce energy investment funds. On account of lead anodes, which can't be framed as precisely as a lattice, opposition misfortunes bring about shower warming, requiring further energy for cooling. In this manner, platinised titanium anodes can give energy reserve funds both in warming and cooling which, thusly, permits the plating science to be more straightforward to oversee and keep up with.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

3f25f0bf-3691-4260-a18e-661a234d0a33|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

May 10, 2021 16:35 by

admin

adminPlatinized rod used in cantiliver anodes with active part of plating to protect the gigantic pump internals, suction, condenser box and pipelines etc.,

Platinum is an excellent catalyst due to its high conductivity and low consumption rate. Platinum deposition made by electroplating method over a high corrosion resistance substrate (Titanium). Since Titanium substrates is having non-corrosive nature form by insulating oxide film by platinum plantings.

Platinized titanium rod are usually used in cantilever anode which is used for protecting pipeline internals, suction and condenser box internal for 30 years and more by applying DC current with transformer rectifier. Normally titanium is well known for its high resistance to corrosion both water and chemical media but titanium is the poor electricity conductor. So we use platinum/ MMO plating/ Coating to increase the conductivity.

Advantages:

- Ø Low consumption rate that conserves precious platinum.

- Ø Favorable dimensional stability.

- Ø Corrosion resistance ensures durability with easy maintainability of the cathode to be protects.

- Ø Light weight, as well as favorable current distribution in electroplating.

Tianno (Ti Anode Fabricators Pvt Ltd, Chennai, India) manufacturing and supplying platinized anodes and cathodic production based on titanium, niobium and other exotic metals. We produce a wide variety of standard and customized anode shapes to maximize your benefit. Below product is recently supplied to Saudi Arabia.

d9eee310-cdef-43a9-959d-7dcb46ce2fb9|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

September 9, 2020 16:25 by

admin

adminSome customer go for Platinised cantilever anode instead of MMO coated Cantilever anode to increase the life of the anode and reduce the replacement cycle. Platinum is one of the best conductor and also increase the life of the anode.

Tiaano supplying Platinised Titanium Cantilever anode and Reference Electrodes for cathodic protection.

01bb9089-c3a7-46ba-8cd4-21643b88bb89|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

December 14, 2019 11:48 by

admin

adminMMO COATED TUBE AND ITS ACCESSORIES

MMO COATED TUBULAR ANODE FOR CATHODIC PROTECTION USED TO PROTECT THE PIPE LINES, DEEP WELLS AND INFRASTRUCTURE LAID IN DIFFERENT APPLICATION LIKE SEA WATER, BRAKISH WATER, SAND ETC.,

MMO COATED TUBULAR ANODE

MMO COATED TUBULAR ANODE will be supply in two types

1. Single string (consist of a single anode with cable)

2. Multi string (consist of two or more anodes connecting with a string)

Anodes are connected with the cable by a) LIDA connection b) CPCC connection.

(20 years Lifetimes stated are nominal, we can supply Amps / life different to stated standards on request)

TIAANO' S RECENT SUPPLY TO HYDERABAD - MMO COATED TUBULAR ANODE (SINGLE STRING)

19043e9d-838d-49dc-8b05-bcd849970688|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c