October 27, 2022 11:31 by

admin

adminAg/Agcl Reference Electrode is the silver/silver chloride reference electrode is composed of a silver wire, sometimes coated with a layer of solid silver chloride, immersed in a solution that is saturated with potassium chloride and silver chloride.

Platinum titanium is a platinum metal oxide or platinum layer-coated on a titanium substrate. It is non-consumption, durable, and insoluble in the electrolyte. We can use platinum titanium anode for cathodic protection and electroplating.

Zinc Reference electrodes are generally implemented for the purpose of monitoring the anode in cathodic protection of buried or immersed metallic structures. It is made of high-purity Zinc alloy, ensuring accuracy and stability of potential measurements.

The electrode frame is made of stainless steel, coated carbon steel or Rubber. The electrode can be designed to fix in the structure. By means of specifically designed supports.

Cu/CuSO4 portable reference electrode implements a major usage in the cathodic protection System. Reference Electrode are in different shapes like disc, rod and strip with different dimension, which is also installed in the Heat exchanger to monitor the current supply of cantilever anodes.

MMO coated Canister anodes are commonly used for impressed current anode cathodic protection applications. These can be used to protect buried metallic piping in congested plant environments, to protect distribution or transmission pipelines in either distributed shallow ground beds or as horizontal remote ground bed anodes, and to protect other structures such as above ground or buried tanks and piling systems.

- Flexibility to meet various user needs;

- Produce complex shape of the anode;

- Energy-saving;

- Lightweight (especially the mesh grid anode);

- Longer working life under higher current density;

- Firm titanium structure, less deformation;

- Second platinized allowed;

- Uniform deposit, final products with high quality.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

2d2a88cb-3b4d-4659-962e-3192c0b71231|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 22, 2022 12:54 by

admin

adminPlatinum titanium is a platinum metal oxide or platinum layer-coated on a titanium substrate. It is non-consumption, durable, and insoluble in the electrolyte. We can use platinum titanium anode for cathodic protection and electroplating.

Zinc Reference electrodes are generally implemented for the purpose of monitoring the anode in cathodic protection of buried or immersed metallic structures. It is made of high-purity Zinc alloy, ensuring accuracy and stability of potential measurements.

The electrode frame is made of stainless steel, coated carbon steel or Rubber. The electrode can be designed to fix in the structure. By means of specifically designed supports.

Ag/Agcl Reference Electrode is the silver/silver chloride reference electrode is composed of a silver wire, sometimes coated with a layer of solid silver chloride, immersed in a solution that is saturated with patassium chloride and silver chloride.

The Reference Electrode implements a major usage in the cathodic protection System. Reference Electrode are in different shapes like disc, rod and strip with different dimension, which is also installed in the Heat exchanger to monitor the current supply of Cantilever anodes.

- Flexibility to meet various user needs

- Produce complex shape of the anode

- Energy-saving

- Lightweight (especially the mesh grid anode)

- Longer working life under higher current density

- Firm titanium structure, less deformation

- Second platinized allowed;

- Uniform deposit, final products with high quality.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

ee10be0d-ddf1-4f33-97e4-a1b913433851|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 13, 2022 09:24 by

admin

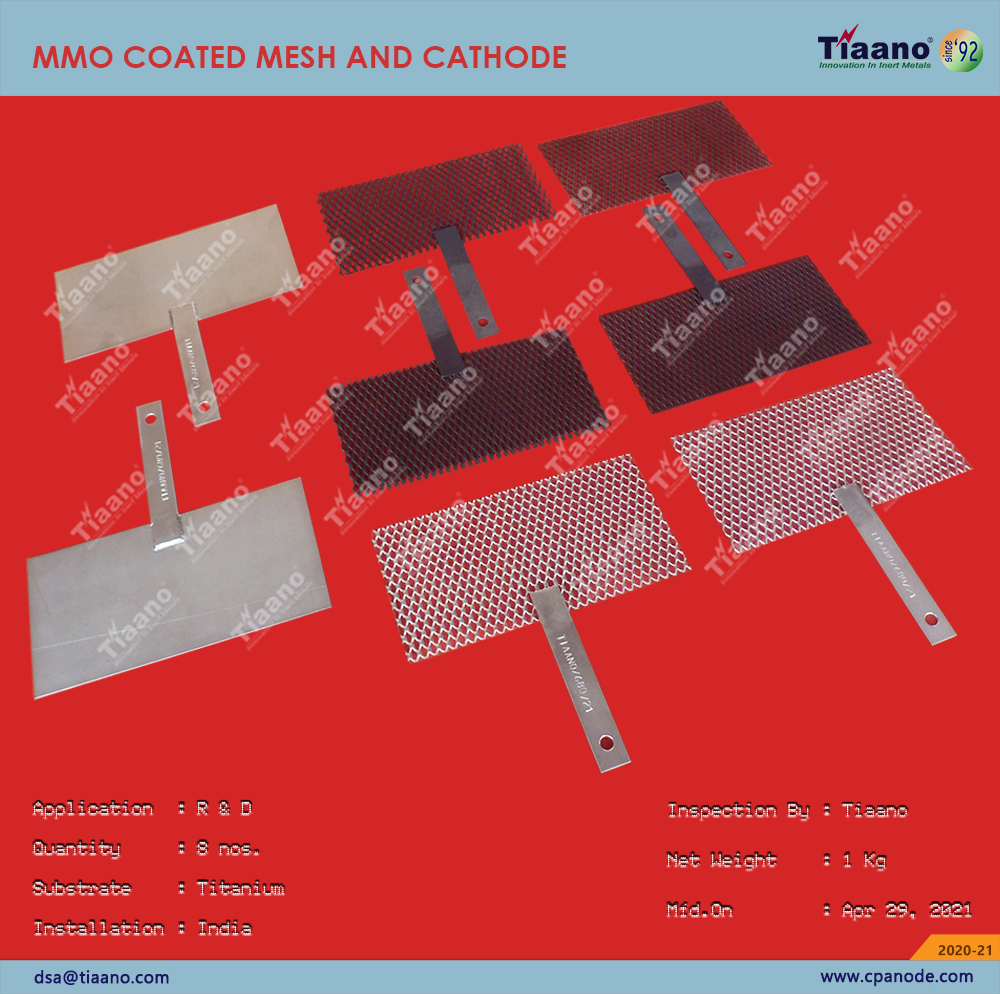

adminWe Tiaano do fabrication & supply of MMO Coated Mesh & Negative Mesh for the generation of Water treatment. We have vast experience in the field of making all kind of MMO coated and Platinum plated anodes. Along with the same and we have supplied the Negative Mesh (Titanium Mesh) / Negative plate (Titanium plates) as per the customer specification.

Water treatment is any process that improves the quality to make the water purified to end use. The end use may be drinking, industrial water supply, irrigation, river flow maintenance, water recreation or many other uses, including being safely returned to the environment.

Water treatment removes contaminants and undesirable components, or reduces their concentration so that the water becomes fit for its desired end-use. This treatment is crucial to human health and allows humans to benefit from both drinking and irrigation use.

Water treatment eliminates pollutants and unwanted parts, or reduces their focus so the water becomes fit for its ideal end-use. This treatment is significant to human wellbeing and permits people to profit from both drinking and water system use Titanium resists all forms of corrosive attack by fresh water.

The corrosion rate is very low or a slight weight gain is experienced. MMO coated titanium anodes are used in a variety of environments, including seawater, brackish water, freshwater, carbon backfill and concrete, due to their significant advantages.

Advantages of MMO anodes:

· Proven reliability.

· Long life span.

· Multiple anode configurations available.

· Lightweight

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

35228aa7-3d80-4a7c-9115-ff85861d7576|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 2, 2022 17:46 by

admin

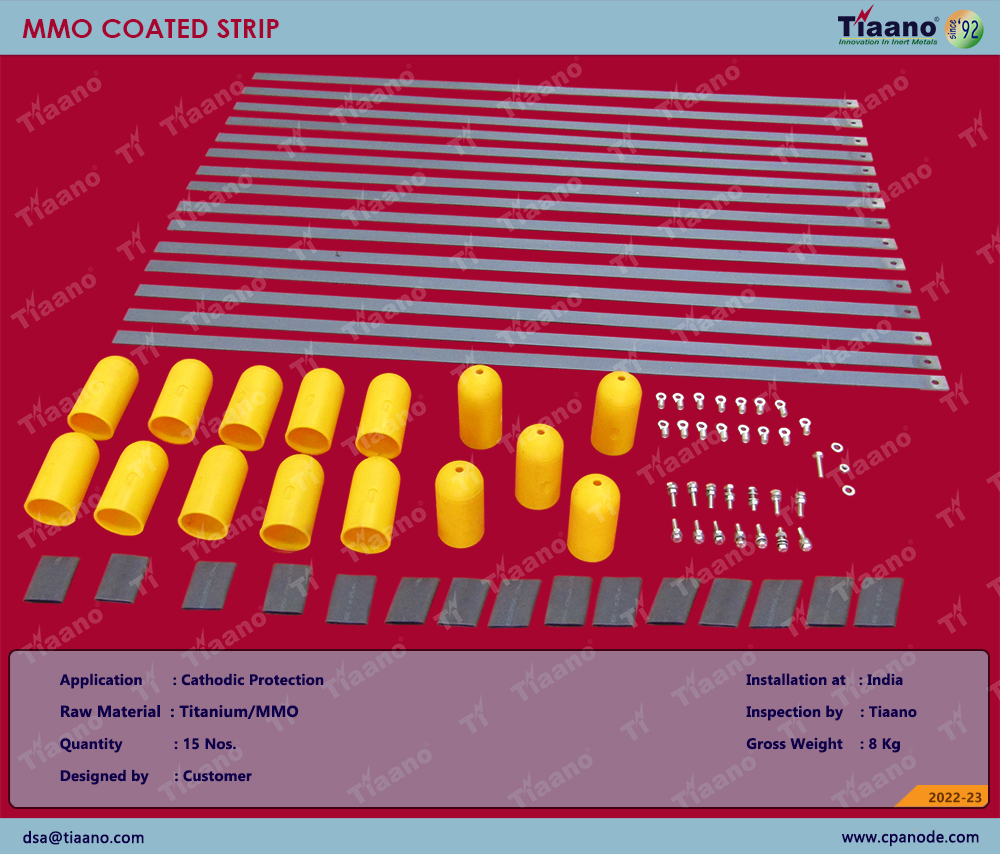

adminStrip anode is mostly utilized for the erosion insurance of seawater structure, Pilings, Piers, Jetties and drifting vessels and so on. Normally these anodes are utilized in the security of Seawater Application. Strip anode is a vital part for Cathodic Protection frameworks in seawater structures. It is made out of a valuable metal blended oxide impetus in the titanium plates by warm cycle.

Titanium strip anodes are fabricated utilizing titanium ASTM B 265 Gr. 1 or 2, Coated with Platinum bunch valuable metal blended oxide covering. MMO covering comprises of Ir and Ta and it is appropriate for use in all cathodic assurance applications. Since blended metal oxide anodes have a very low utilization rate, the titanium substrate stays consistent over the plan lifetime of the anode.

The leading anti-corrosion & uniform current distribution characters, it have great physical and mechanical properties of titanium. MMO covered anodes are emphatically suggested for Impressed Current Cathodic Protection (ICCP) application. We likewise fabricated and provided FRP Insulated Strip anode for different clients.

Impressed Current Cathodic Protection systems are the ultimate solution for all corrosion problems to protect the metallic structure for long time and are recognized as a superior alternative to sacrificial anode systems which require frequent replacement. Impressed current cathodic protection systems are preferred by ship owners because they reduce fuel cost and maintenance.

MMO Coated strip is used for concrete protection like jetty pile, underground pipes, pillars etc. Tiaano supplying FRP insulated strips with catalyst of MMO and Platinised. Tubular string anodes are used to protect the underground pipe lines from corrosion.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

904334f7-049f-454f-9a51-57fbcc64adb5|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 1, 2022 15:57 by

admin

adminPlatinized titanium and MMO coated titanium rod anodes are to be designed & manufactured by Ti Anode Fabricators Pvt Ltd, Chennai, India. Application: Deep & conventional ground beds. Jetties in fresh and brackish.

Substrate: Solid Titanium and Niobium & Copper cored Ti. Catalyst for surface Coating: Platinum Mixed Metasalt-water electrolytes. Water tanks. Lock Gates. Intake Screens. Marine application Oxide

Platinized Titanium and Niobium probe / cantilever type anodes are also available for use in Internal ICCP of process vessels such as pipes, condenser water boxes and heat exchangers where the interior is difficult to access and its space limited. Such anodes are often mounted through the vessel shell, with the anode part of the probe extending into the vessel, and wire connections made to the probe on the exterior of the vessel.

Tiaano offer Platinised Titanium and Niobium cantilever (probe) anodes for this application (medium seawater, fresh water and brackish water) Also Tiaano offer platinized Rods and Tubes suitable for cantilevers (probes).

The primary use of platinized titanium anodes is in the field of Cathodic Protection. The anodes are used in structures buried in soil and the steel exposed to marine environments such as oil and gas producing platforms, ships, oil well casings and jetties.

Platinized Titanium Anodes synergistically combine the favourable electrochemical features of platinum (Pt) with the corrosion resistance and other characteristics of titanium. They are anodes normally produced by the electrochemical deposition of a very thin layer of platinum metal onto a titanium substrate. These anodes operate as inert anodes with high durability and are preferred because they remain insoluble in common electrolytes.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

1c06246a-337e-467d-a062-b988590ae303|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

July 30, 2022 16:35 by

admin

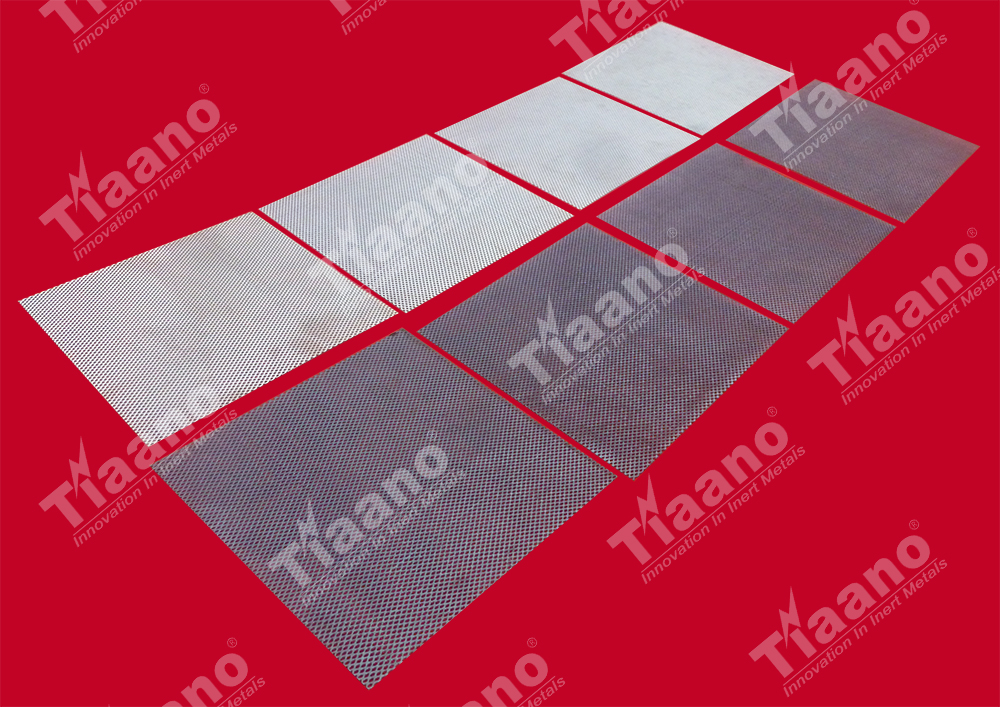

adminMMO coated mesh is simply a titanium, coated with Mixed Metal Oxides. MMO titanium anodes act as inert anodes and are non-consumable and long lasting. These anodes are insoluble in electrolysis. Since No other metal having the stability than the MMO Coated Titanium Mesh. We supply different sizes of mesh and plates for various industries.

Tiaano design, fabricate, manufacture and supply various types and size of mesh for various applications. Research and development (R&D) includes activities that companies undertake to innovate and introduce new products. It is the first stage in the development process of new products and leads to get more orders. Tiaano producing platinized wire in various diameters as per customer needs.

MMO Coated Anodes are widely used in many industries, having special chemical & physical properties like high corrosion resistance, thermal conductivity and catalytic nature. Being a very expensive metal, instead of using solid form, platinum is deposited on the surface of titanium or niobium, occasionally on molybdenum by micron level layer. Anodes are available with hanging hook, frame or band in the form of sheet, mesh, pipe, wire, rod and custom built.

- Energy saving potential

- Low weight (in particular expanded metal anodes)

- Long service time even at high current density

- Dimensional stability, long durability of base material

- Recoating possible

- Higher quality of end product

- Application-specific design

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

0c9011bb-bba0-484b-b6b7-85123a8891ca|0|.0|27604f05-86ad-47ef-9e05-950bb762570c