October 31, 2022 16:48 by

admin

admin Cathodic protection is the most common electrochemical technique used to prevent corrosion on pipelines, storage tanks, ship hulls, underground tanks etc. The process occurs when a DC current is passed through an anode and cathode so that the metal becomes cathodic and prevents corrosion.

Cathodic protection is one of the main technique to prevent corrosion. Cathodic protection is of two types they are Impressed Current Cathodic Protection (ICCP) and Galvanic Protection also known as DCCP. Cathodic protection systems protects a wide range of metallic structures in various environments.

Titanium tubular anodes are manufactured using titanium seamless tube and coated with platinum group precious metal mixed oxide coating.

Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements.

Mixed metal oxide based electro catalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current.

Mixed Metal Oxide anodes are typically rated for a given output and life, for example 5 amps at 20 years. Within the normal range of current discharge for MMO anodes, this relationship is linear. The same 5 amp anode rated for 20 years of service would provide 40 years if only operated at 2.5 amps.

Benefits of MMO Coated Tubular String:

· Lightweight/Durable

· High current output

· Low cost

· Dimensionally stable

· High cost performance

MMO Coated Tubular String - Applications:

· Salt, fresh and brackish water

· Deep well Anodes

· Marine applications

· Tank bottoms

The specification of the below displayed MMO Coated Titanium Tubular String Anode

|

Material

|

Titanium

|

|

Dimensionally

|

Stable

|

|

Thickness

|

0.9 mm

|

|

Country of origin

|

India

|

|

OD

|

25.4 mm

|

|

Length

|

500 mm

|

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

a0ca1f8b-bbae-43f8-a311-0c6ee7a690bc|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

October 27, 2022 11:31 by

admin

adminAg/Agcl Reference Electrode is the silver/silver chloride reference electrode is composed of a silver wire, sometimes coated with a layer of solid silver chloride, immersed in a solution that is saturated with potassium chloride and silver chloride.

Platinum titanium is a platinum metal oxide or platinum layer-coated on a titanium substrate. It is non-consumption, durable, and insoluble in the electrolyte. We can use platinum titanium anode for cathodic protection and electroplating.

Zinc Reference electrodes are generally implemented for the purpose of monitoring the anode in cathodic protection of buried or immersed metallic structures. It is made of high-purity Zinc alloy, ensuring accuracy and stability of potential measurements.

The electrode frame is made of stainless steel, coated carbon steel or Rubber. The electrode can be designed to fix in the structure. By means of specifically designed supports.

Cu/CuSO4 portable reference electrode implements a major usage in the cathodic protection System. Reference Electrode are in different shapes like disc, rod and strip with different dimension, which is also installed in the Heat exchanger to monitor the current supply of cantilever anodes.

MMO coated Canister anodes are commonly used for impressed current anode cathodic protection applications. These can be used to protect buried metallic piping in congested plant environments, to protect distribution or transmission pipelines in either distributed shallow ground beds or as horizontal remote ground bed anodes, and to protect other structures such as above ground or buried tanks and piling systems.

- Flexibility to meet various user needs;

- Produce complex shape of the anode;

- Energy-saving;

- Lightweight (especially the mesh grid anode);

- Longer working life under higher current density;

- Firm titanium structure, less deformation;

- Second platinized allowed;

- Uniform deposit, final products with high quality.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

2d2a88cb-3b4d-4659-962e-3192c0b71231|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

October 11, 2022 17:20 by

admin

adminWe, Ti anode fabricators Pvt. Ltd., is familiar in manufacturing and supplying of Platinum Plated Cantilever for impressed current cathodic production (ICCP)

Platinum is an amazing catalyst because of its high conductivity and low utilization rate. Platinum testimony made by electroplating strategy over a high erosion opposition substrate. Platinum is a most un-responsive metals that has surprising protection from consumption, even at high temperatures. Cathodic security is a technique for forestalling erosion on lowered and underground metallic designs. Cathodic insurance is one of the best technique for forestalling consumption on a metal surface.

Platinized cantilever anode is utilized for safeguarding pipeline internals, pull and condenser box inner for a long time and more by applying DC current with transformer rectifier. Ordinarily titanium is notable for its high protection from erosion both water and chemical media but titanium is the poor electricity conductor. So we use platinum/MMO plating/coating to expand the conductivity.

Impressed Current Cathodic Protection is one of the best system to prevent corrosion by passing DC current through anodes and cathodes from one end to another end. platinised titanium anode is used for protecting pipeline internals, suction and condenser box internal for 30 years and more by applying DC current with transformer rectifier. We use platinum/ MMO plating/ coating to increase the conductivity.

ADVANTAGES:

- Low utilization rate that preserves valuable platinum.

- Favorable dimensional stability.

- Corrosion resistance ensures durability with easy maintainability.

- Light weight, as well as favorable current distribution in electroplating.

Applications:

- Heat exchangers.

- Pumps

- Valves

- Pipes

- Marine application

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

f021753c-96ff-43c1-afbb-eb8ed419a280|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

October 11, 2022 14:05 by

admin

adminWe, Ti anode fabricators Pvt. Ltd., is familiar in manufacturing and supplying of Platinum Plated Cantilever for impressed current cathodic production (ICCP)

Platinum is an amazing catalyst because of its high conductivity and low utilization rate. Platinum testimony made by electroplating strategy over a high erosion opposition substrate. Platinum is a most un-responsive metals that has surprising protection from consumption, even at high temperatures. Cathodic security is a technique for forestalling erosion on lowered and underground metallic designs. Cathodic insurance is one of the best technique for forestalling consumption on a metal surface.

Platinized cantilever anode is utilized for safeguarding pipeline internals, pull and condenser box inner for a long time and more by applying DC current with transformer rectifier. Ordinarily titanium is notable for its high protection from erosion both water and chemical media but titanium is the poor electricity conductor. So we use platinum/MMO plating/coating to expand the conductivity.

Impressed Current Cathodic Protection is one of the best system to prevent corrosion by passing DC current through anodes and cathodes from one end to another end. platinised cantilever anode is used for protecting pipeline internals, suction and condenser box internal for 30 years and more by applying DC current with transformer rectifier. We use platinum/ MMO plating/ coating to increase the conductivity.

ADVANTAGES:

- Low utilization rate that preserves valuable platinum.

- Favorable dimensional stability.

- Corrosion resistance ensures durability with easy maintainability.

- Light weight, as well as favorable current distribution in electroplating.

Applications:

- Heat exchangers.

- Pumps

- Valves

- Pipes

- Marine application

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

72b7c9cc-5c1f-4b04-9fdd-6ca585495e48|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

September 19, 2022 16:49 by

admin

adminWe, Ti Anode Fabricators Pvt. Ltd., developed an extremely strong and electrically low resistance centre crimp connection, which ensures the lowest possible electrical resistance (less than 1.0 Milli Ohm) between the cables and anode tube. The Platinum group Mixed Metal Oxide coating is a crystalline electrically conductive coating that activates and enables a titanium substrate to function as an anode. Whether operating in fresh water, seawater, soil, or mud. MMO Coatings are extremely stable even in very low pH environments.

MMO Coated Tubular String are coated with mixed metal oxide that has an extremely low consumption rate measured in milligrams per year. Unlike other types of anodes the consumption rate of MMO anode is negligible with the dimensions of the anode element remaining virtually unchanged during the operational service life of the anode. As a result, the power required to impress current will remain the same.

Cathodic Protection system is a technique used to control a corrosion of a metal surface by making it the cathodic side of an electrochemical cell. Cathodic protection is an old and effective system that prevents forming rust in metal and helps in corrosion resistant. Corrosion can be prevented by eliminating the oxygen or the positively charged hydrogen ions.

|

Material

|

MMO Titanium

|

|

Usage/Application

|

Cathodic Protection ICCP

|

|

Brand

|

Tiaano

|

|

Thickness

|

Wall Thickness 0.9 mm

|

|

Country of Origin

|

Made in India

|

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

4ed58342-da2e-47bc-b024-eb39d8dd3e2b|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

September 19, 2022 14:39 by

admin

adminTitanium tubular anodes are manufactured using titanium seamless tube and coated with platinum group precious metal mixed oxide coating. Titanium tubular string for pipelines are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements

Mixed Metal Oxide Coated Titanium anode design for the demands of deep anode beds, shallow beds and the earth’s natural waters. MMO Tubular anodes are dimensionally stable anodes which remain constant throughout all of the anode life, thus providing a constant performance with a low resistivity

MMO Titanium tubular anodes are a titanium tube base with a mixed metal oxide conductive coating and itself an excellent electronic conductor.

The design life of the anode varies with operating current in a variety of applications from seawater to soil. Tubular Anodes are available in a number of diameters, lengths, current carrying capacities and life ratings.

MMO tubular anode can be in single or in string, it is generally adopting titanium tubular as substrates and coated with a mixed metal oxide catalyst.

Mixed metal oxide based electro catalytic anodes are a different type of anodes when compared to conventional anodes. These anodes are dimensionally stable, long life anodes that are not consumed during the process of generating cathodic protection current.

Mixed Metal Oxide anodes are typically rated for a given output and life, for example 5 amps at 20 years. Within the normal range of current discharge for MMO anodes, this relationship is linear. The same 5 amp anode rated for 20 years of service would provide 40 years if only operated at 2.5 amps.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

cd06c6dc-a550-4319-8b3a-888c05a953e6|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 22, 2022 12:54 by

admin

adminPlatinum titanium is a platinum metal oxide or platinum layer-coated on a titanium substrate. It is non-consumption, durable, and insoluble in the electrolyte. We can use platinum titanium anode for cathodic protection and electroplating.

Zinc Reference electrodes are generally implemented for the purpose of monitoring the anode in cathodic protection of buried or immersed metallic structures. It is made of high-purity Zinc alloy, ensuring accuracy and stability of potential measurements.

The electrode frame is made of stainless steel, coated carbon steel or Rubber. The electrode can be designed to fix in the structure. By means of specifically designed supports.

Ag/Agcl Reference Electrode is the silver/silver chloride reference electrode is composed of a silver wire, sometimes coated with a layer of solid silver chloride, immersed in a solution that is saturated with patassium chloride and silver chloride.

The Reference Electrode implements a major usage in the cathodic protection System. Reference Electrode are in different shapes like disc, rod and strip with different dimension, which is also installed in the Heat exchanger to monitor the current supply of Cantilever anodes.

- Flexibility to meet various user needs

- Produce complex shape of the anode

- Energy-saving

- Lightweight (especially the mesh grid anode)

- Longer working life under higher current density

- Firm titanium structure, less deformation

- Second platinized allowed;

- Uniform deposit, final products with high quality.

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

ee10be0d-ddf1-4f33-97e4-a1b913433851|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 22, 2022 11:31 by

admin

admin

Platinized titanium anode by adopting a thermal decomposition process to get a dense wear-resistant layer of platinum coating. They can modify the anode surface to improve the adhesion of platinum and the uniformity of coating thickness.

Platinum titanium is a platinum metal oxide or platinum layer-coated on a titanium substrate. It is non-consumption, durable, and insoluble in the electrolyte. We can use platinum titanium anode for cathodic protection and electroplating.

Platinum is a highly valued metal, and it is widely used in jewelry, engines, and industrial machinery.

We can customize the anode with different shapes such as mesh, rod, sheet, tube to suit various application areas.

Platinized titanium anode has both high anti-corrosion qualities and excellent platinum electrochemical performance. It is more advantageous as compared to other lead anode and soluble electrodes.

- Flexibility to meet various user needs

- Produce complex shape of the anode

- Energy-saving

- Lightweight (especially the mesh grid anode)

- Longer working life under higher current density

- Firm titanium structure, less deformation

- Second platinized allowed

- Uniform deposit, final products with high quality

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

baa9877b-1d02-4fdd-9389-705928899130|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 13, 2022 09:24 by

admin

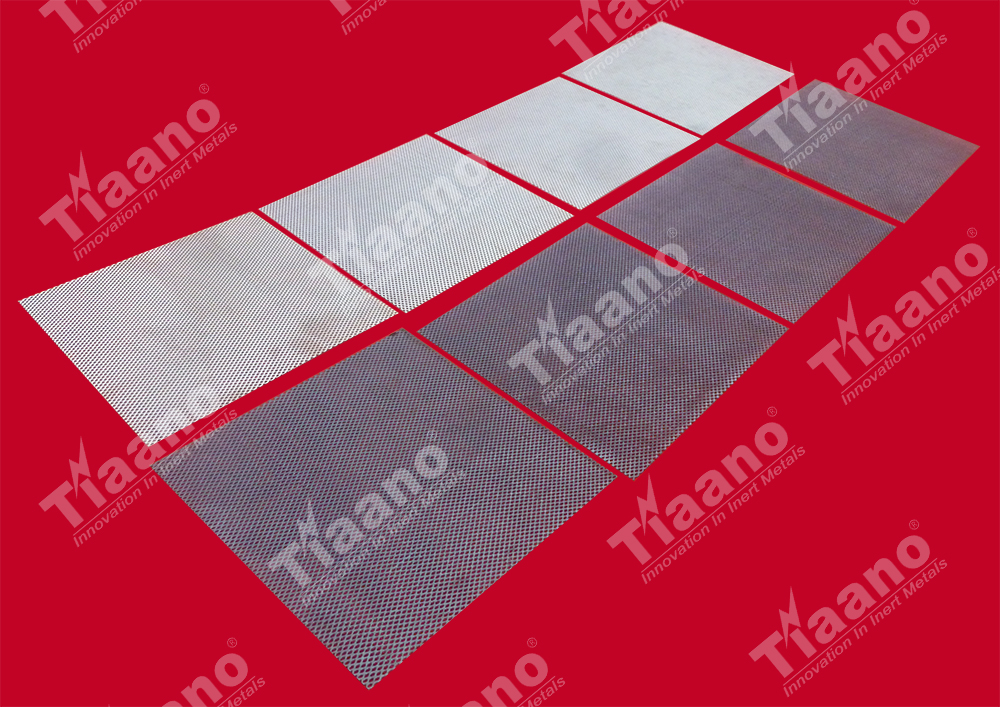

adminWe Tiaano do fabrication & supply of MMO Coated Mesh & Negative Mesh for the generation of Water treatment. We have vast experience in the field of making all kind of MMO coated and Platinum plated anodes. Along with the same and we have supplied the Negative Mesh (Titanium Mesh) / Negative plate (Titanium plates) as per the customer specification.

Water treatment is any process that improves the quality to make the water purified to end use. The end use may be drinking, industrial water supply, irrigation, river flow maintenance, water recreation or many other uses, including being safely returned to the environment.

Water treatment removes contaminants and undesirable components, or reduces their concentration so that the water becomes fit for its desired end-use. This treatment is crucial to human health and allows humans to benefit from both drinking and irrigation use.

Water treatment eliminates pollutants and unwanted parts, or reduces their focus so the water becomes fit for its ideal end-use. This treatment is significant to human wellbeing and permits people to profit from both drinking and water system use Titanium resists all forms of corrosive attack by fresh water.

The corrosion rate is very low or a slight weight gain is experienced. MMO coated titanium anodes are used in a variety of environments, including seawater, brackish water, freshwater, carbon backfill and concrete, due to their significant advantages.

Advantages of MMO anodes:

· Proven reliability.

· Long life span.

· Multiple anode configurations available.

· Lightweight

For Enquiries please drop your email at dsa@tiaano.com|dsasupport@tiaano.com

35228aa7-3d80-4a7c-9115-ff85861d7576|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 2, 2022 17:46 by

admin

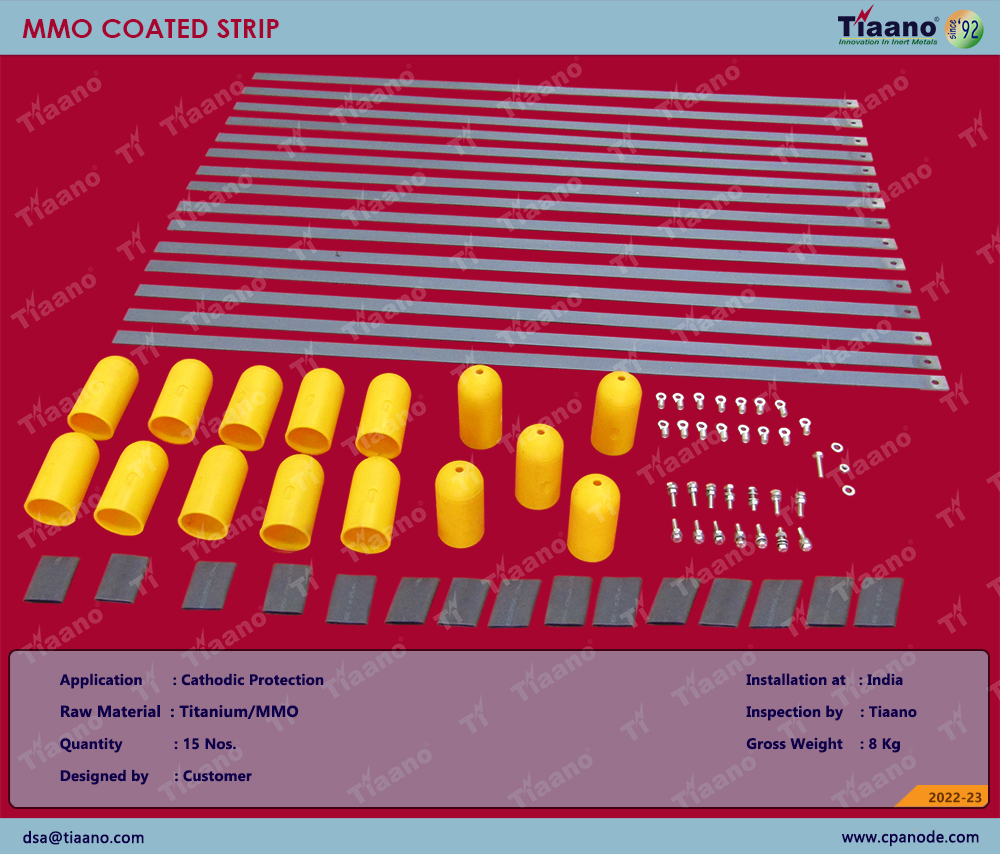

adminStrip anode is mostly utilized for the erosion insurance of seawater structure, Pilings, Piers, Jetties and drifting vessels and so on. Normally these anodes are utilized in the security of Seawater Application. Strip anode is a vital part for Cathodic Protection frameworks in seawater structures. It is made out of a valuable metal blended oxide impetus in the titanium plates by warm cycle.

Titanium strip anodes are fabricated utilizing titanium ASTM B 265 Gr. 1 or 2, Coated with Platinum bunch valuable metal blended oxide covering. MMO covering comprises of Ir and Ta and it is appropriate for use in all cathodic assurance applications. Since blended metal oxide anodes have a very low utilization rate, the titanium substrate stays consistent over the plan lifetime of the anode.

The leading anti-corrosion & uniform current distribution characters, it have great physical and mechanical properties of titanium. MMO covered anodes are emphatically suggested for Impressed Current Cathodic Protection (ICCP) application. We likewise fabricated and provided FRP Insulated Strip anode for different clients.

Impressed Current Cathodic Protection systems are the ultimate solution for all corrosion problems to protect the metallic structure for long time and are recognized as a superior alternative to sacrificial anode systems which require frequent replacement. Impressed current cathodic protection systems are preferred by ship owners because they reduce fuel cost and maintenance.

MMO Coated strip is used for concrete protection like jetty pile, underground pipes, pillars etc. Tiaano supplying FRP insulated strips with catalyst of MMO and Platinised. Tubular string anodes are used to protect the underground pipe lines from corrosion.

FOR ENQUIRES PLEASE DROP YOUR EMAIL AT dsa@tiaano.com/dsasupport@tiaano.com

904334f7-049f-454f-9a51-57fbcc64adb5|0|.0|27604f05-86ad-47ef-9e05-950bb762570c