November 18, 2021 15:29 by

admin

adminCathodic protection systems is to protect a wide range of metallic structures in various environments. Common applications or environment to protect is steel, water or fuel pipelines and steel storage tanks such huge oil tanks, chemical storage tanks, steel pier piles, ship and boat hulls, offshore oil platforms and onshore oil well casings and metal reinforcement bars in concrete buildings and structures.

Galvanic or sacrificial anodes are made in various shapes and sizes using alloys of zinc, magnesium and aluminum. In order for galvanic cathodic protection to work, the anode must possess a lower (that is, more negative) electrode potential than that of the cathode (the target structure to be protected). Some old days or still some of them used galvanic anodes to protect the cathode which will be replaceable often that could be very challenging and spent lots of money and time

Now-a-days impressed current cathodic protection (ICCP) systems are used to avoid replacing the cathode in years together like. These consist of anodes connected to a DC power source, often a transformer-rectifier connected to AC power. In the absence of an AC supply, alternative power sources may be used, such as solar panels, wind power or gas powered thermoelectric generators in accordance with the CP designer.

In the absence of an AC supply, alternative power sources may be used, such as solar panels, wind power or gas powered thermoelectric generators in accordance with the CP designer. Tiaano is the leaders to supply different type of cathodic protection anodes over 63 countries especially for power plants in mass supply and still doing well with increasing year to year.

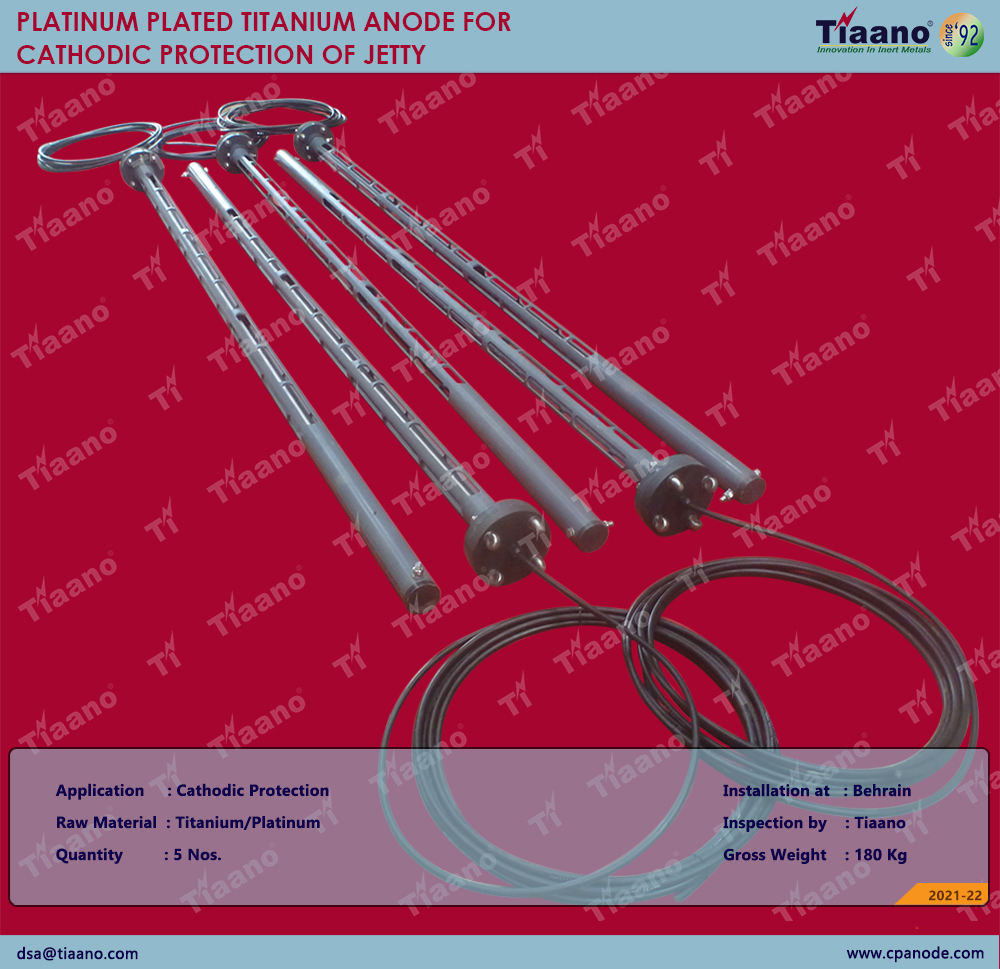

Tiaano is the manufacturing company for many CP solutions from 2003 onwards. Our cathodic protection anodes installed in onshore and offshore platform like jetty piles, underwater bridge and many structures.

Platinum Plated Titanium Anode for Cathodic Protection of Jetty

To know more details about our products visit these links:

1.Click here(Twitter)

2.Click here(Instagram)

3.Click here(Pinterest)

4.Click here(Facebook)

1b3cec24-2a4a-488a-8d4a-d3ca67032838|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

November 17, 2021 16:08 by

admin

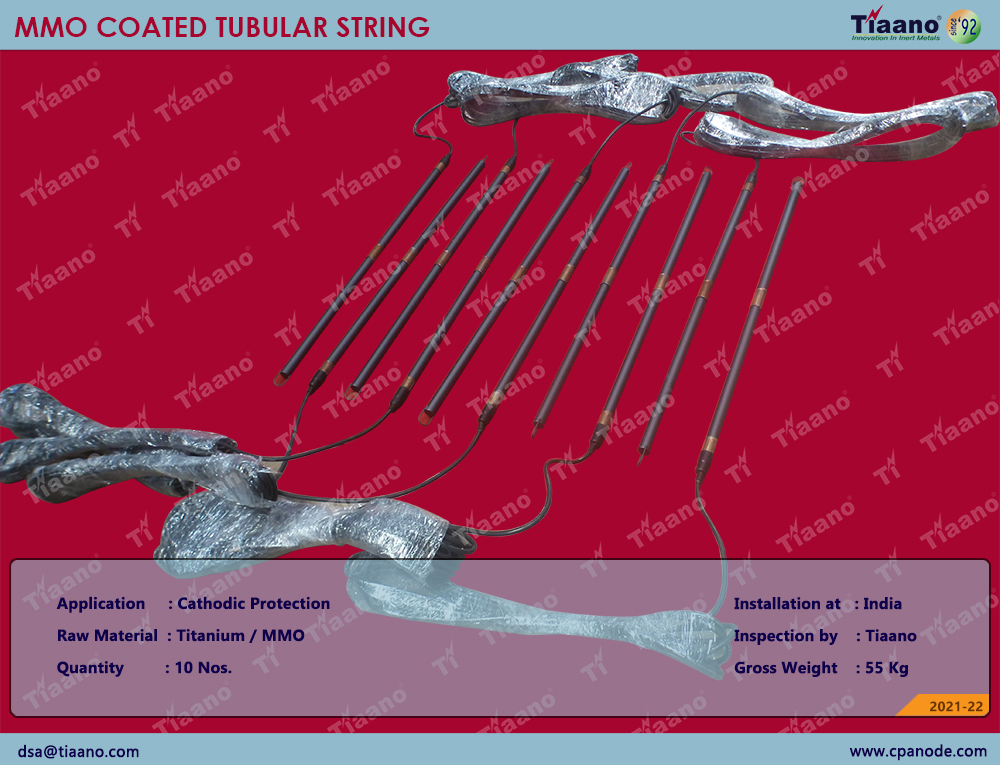

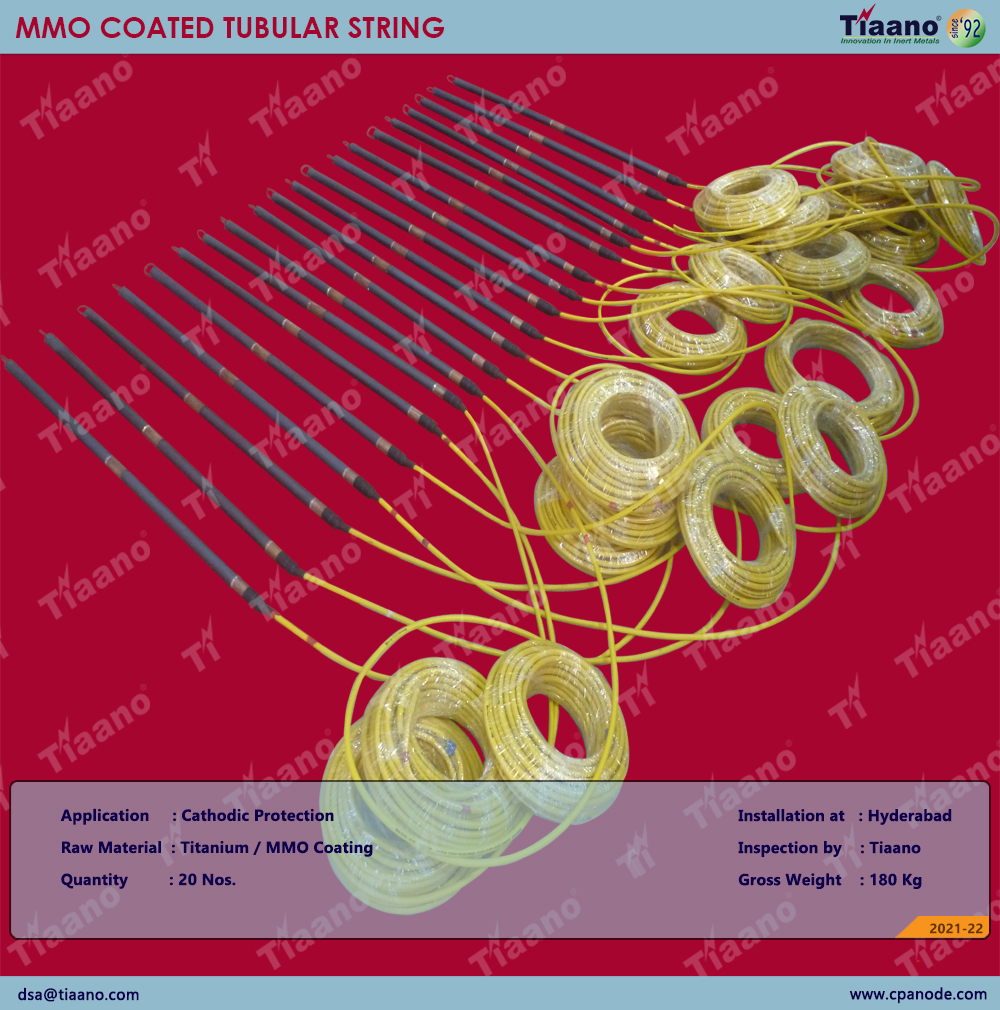

adminWe Tiaano supply some of common anodes are tubular and solid rod shapes or continuous ribbons, mesh of various materials. These anodes are made from Titanium, niobium with mixed metal oxide, platinum coated.

For pipelines, anodes are arranged in ground beds either distributed or in a deep vertical hole depending on several design and field condition factors including current distribution requirements.

Cathodic protection is a technique used to control the corrosion of a metal surface by cathode of an electrochemical cell. A simple method of protection connects the "sacrificial metal" to act as the anode.

To know more details about our products visit these links:

1. https://twitter.com/cp_anodes

2. https://www.instagram.com/cp_anode/

3. https://www.pinterest.it/TiaanoCpAnode/_saved/

4. https://www.facebook.com/cathodicprotectionanodes

0e32b72e-3f61-4f56-b540-89488d8040ec|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

October 16, 2021 14:21 by

admin

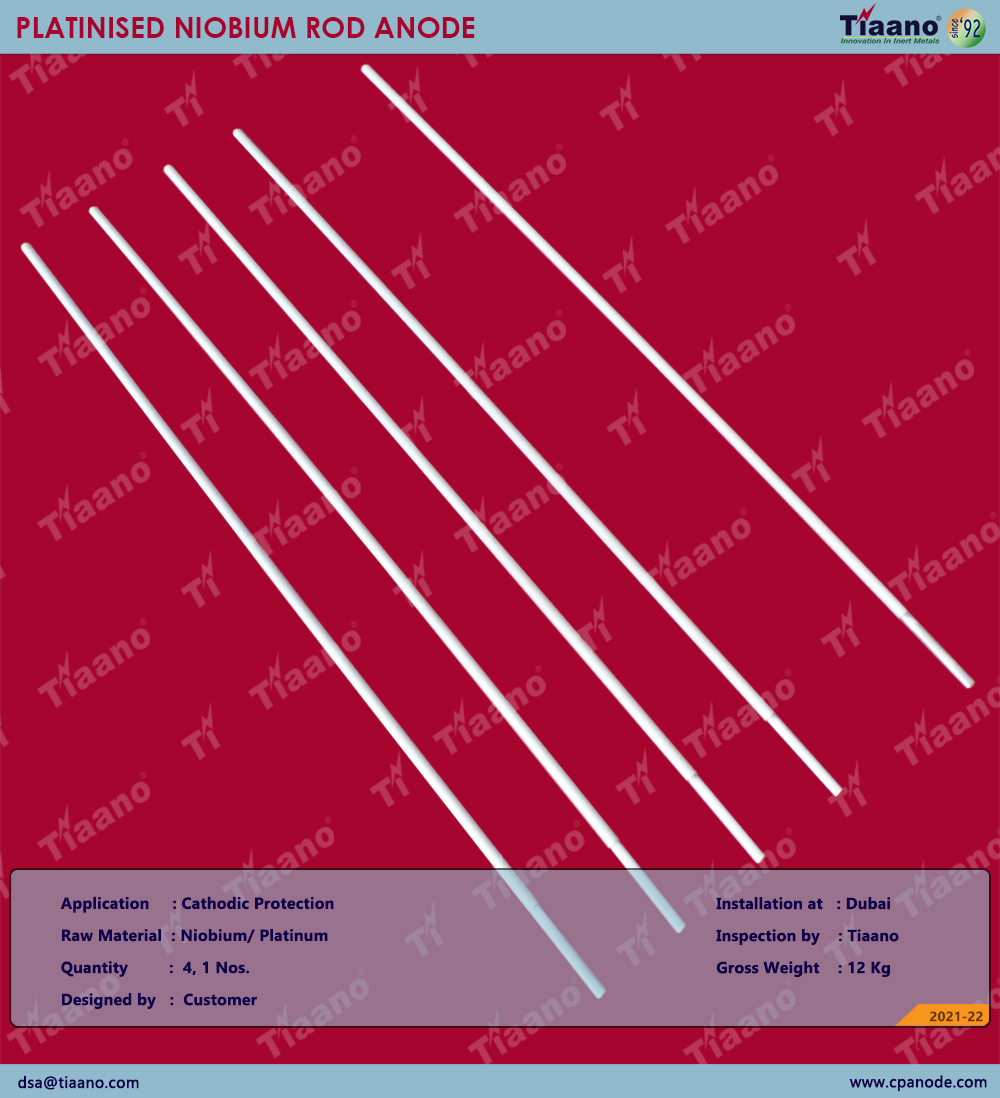

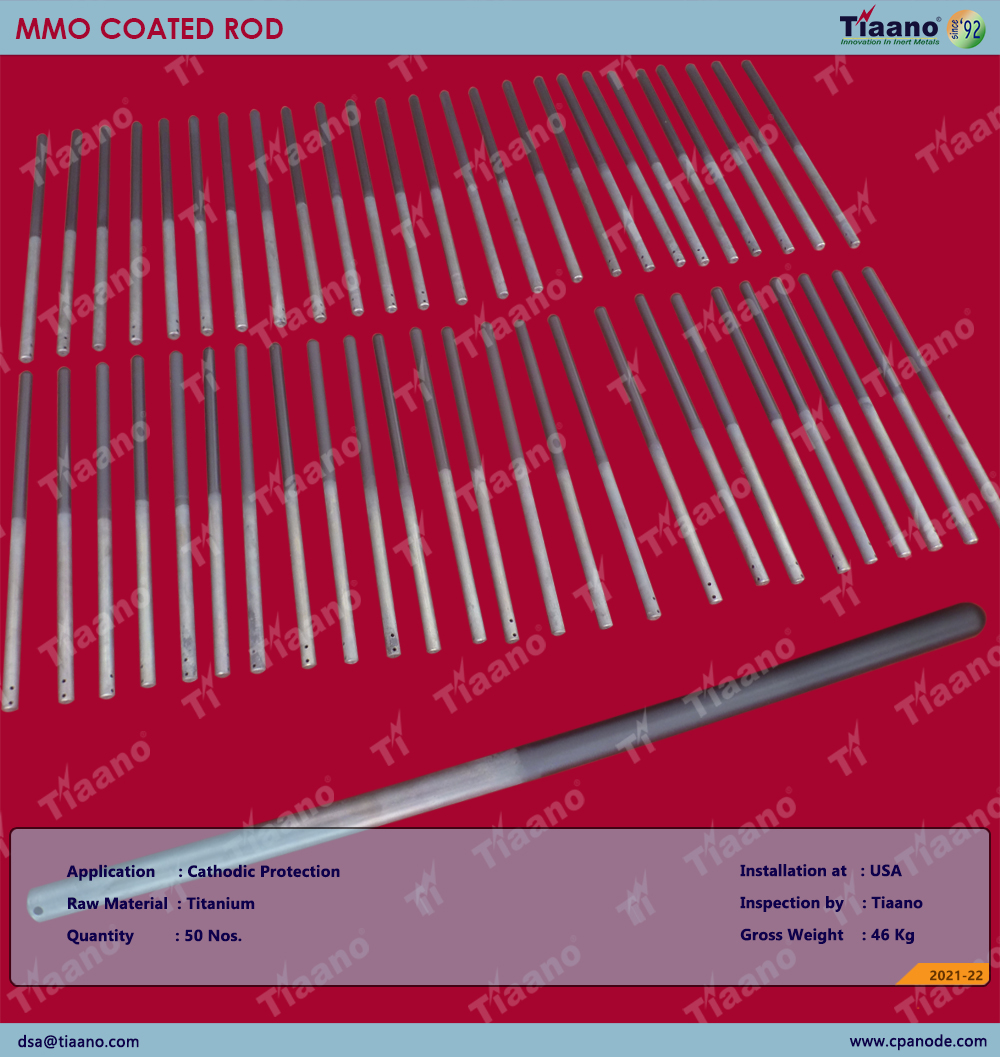

adminWe design, manufacturing and supply MMO & Platinum plated Titanium and Niobium rod anodes for Impressed Current Cathodic Protection (ICCP). According to the customer’s requirement we manufacture the anodes from copper cored titanium and copper cored niobium too.

Cathodic protection is most innovative technique to protect the corrosion of active metal surfaces. Cathodic protection is used all over the globe to protect pipelines, big concrete structures, water treatment plants, above and underwater storage tanks, ship and boat hulls.

For more details visit our site: www.cpanode.com

c209bc1a-672d-4c73-819f-0278117b350c|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

September 3, 2021 16:36 by

admin

adminCathodic protection (CP) is a technique used to control the corrosion of a metal surface. Impressed current systems utilize an external power source that provides protective current to mitigate corrosion activity. Permanently installed anodes and the embedded reinforcing steel are connected to an AC/DC rectifier that forces the steel to a cathodic or protective condition. Impressed current systems provide a high level of protection but should be properly monitored and maintained to ensure long-term performance.

Platinized cantilever anode is used for protecting pipeline internals, suction and condenser box internal for 30 years and more by applying DC current with transformer rectifier. We use platinum/ MMO plating/ coating to increase the conductivity.

de14cb9c-f6c2-436e-b929-4122dfb24ed3|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

September 2, 2021 16:21 by

admin

adminWe The Ti anode fabricators Pvt. Ltd., Chennai design, manufacturing and supply of MMO & Platinum plated Titanium and Niobium anodes for Impressed Current Cathodic Protection (ICCP). According to the customer’s requirement we manufacture the anodes from copper cored titanium and copper cored niobium too.

Our anodes are gone through the accreditation test by M/s. TWT, London as per NACE standard TMO 294-2001.Either the factory made ‘LIDA’ or ‘CPCC’ connected tubular string anodes; anode tubes; anode strings for offshore platforms protection; civil probe anodes; wire anodes, piggy back anodes, anode flex, canister pack anodes; rod anodes; strip anodes; disc anodes; tank bottom ribbon anodes; mesh ribbon anodes; discrete mesh anodes are also in our production scope.

23e103df-781a-421b-8330-13e86001edbd|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 18, 2021 09:43 by

admin

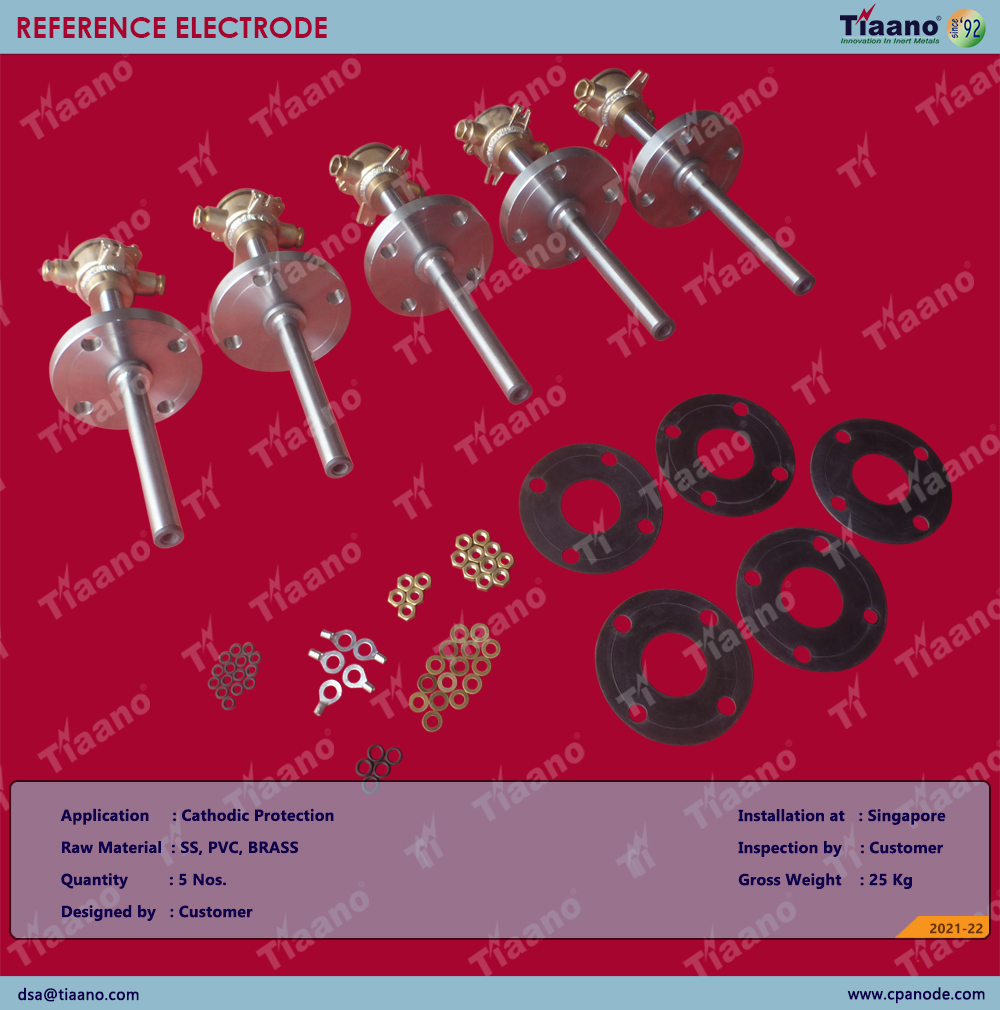

adminReference electrodes are generally implemented for the purpose of monitoring the anode in cathodic protection of buried or immersed metallic structures.

It is made of high-purity of alloys, ensuring accuracy and stability of potential measurements. The electrode frame is made of stainless steel, coated carbon steel or Rubber. The electrode can be designed to fix in the structure. By means of specifically designed supports.

These Reference Electrode implements a major usage in the cathodic protection System. Reference Electrode are in different shapes like disc, rod and strip with different dimension, which is also installed in the Heat exchanger to monitor the current supply of Cantilever anodes.

Cantilever anode is used for protecting pipeline internals, suction and condenser box internal for 30 years and more by applying DC current with transformer rectifier. Normally titanium is well known for its high resistance to corrosion both water and chemical media but titanium is the poor electricity conductor. So we use platinum/ MMO plating/ coating to increase the conductivity.

bb95e280-da96-4c93-9429-b4aa50e56b85|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 17, 2021 11:52 by

admin

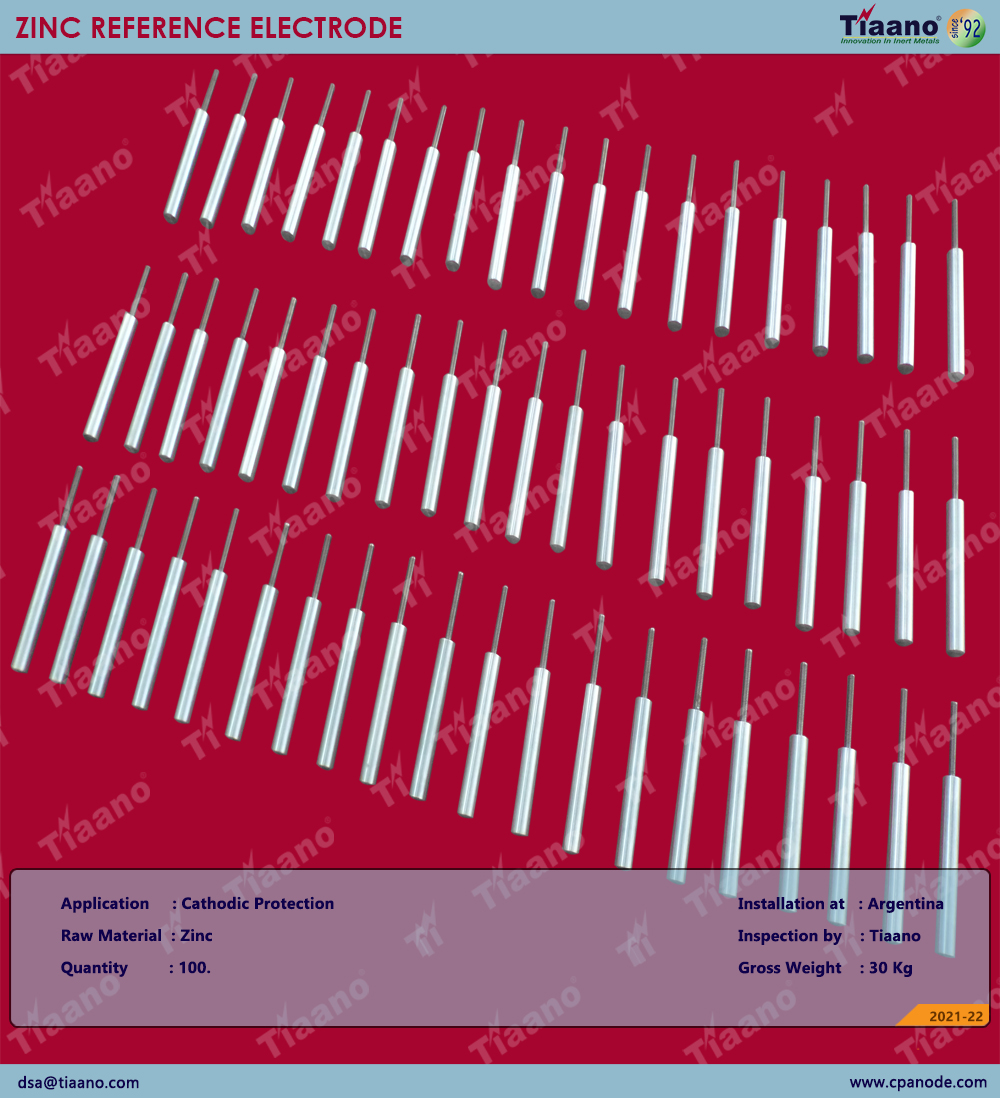

adminZinc Reference electrodes are generally implemented for the purpose of monitoring the anode in cathodic protection of buried or immersed metallic structures.

It is made of high-purity Zinc alloy, ensuring accuracy and stability of potential measurements. The electrode frame is made of stainless steel, coated carbon steel or Rubber. The electrode can be designed to fix in the structure. By means of specifically designed supports.

These Zinc Reference Electrode implements a major usage in the cathodic protection System. Zinc reference Electrode are in different shapes like disc, rod and strip with different dimension, which is also installed in the Heat exchanger to monitor the current supply of Cantilever anodes.

bda6dc44-9e43-46d0-a052-48757703c5e5|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 16, 2021 17:17 by

admin

adminPlatinum is an excellent catalyst due to its high conductivity and low consumption rate. Platinum deposition made by electroplating method over a high corrosion resistance substrate (Titanium). Since Titanium substrate is having non-corrosive nature form by insulating oxide film by platinum plantings.

Platinized cantilever anode is used for protecting pipeline internals, suction and condenser box internal for 30 years and more by applying DC current with transformer rectifier. Normally titanium is well known for its high resistance to corrosion both water and chemical media but titanium is the poor electricity conductor. So we use platinum/ MMO plating/ coating to increase the conductivity.

Advantages:

- Low consumption rate that conserves precious platinum.

- Favorable dimensional stability.

- Corrosion resistance ensures durability with easy maintainability.

- Light weight, as well as favorable current distribution in electroplating.

Tianno manufacturing and supplying various anodes for cathodic production based on titanium, niobium and other exotic metals. We produce a wide variety of standard and customized anode shapes to maximize your benefit.

9224153e-04b3-4feb-9a83-2d64ca27c103|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

August 11, 2021 15:18 by

admin

adminShips are often exposed to very harsh marine environments. Due to the environment in which they operate, the ship’s hull is often exposed sea environmental corrosion that can reduce the life.

The corrosion of seawater as regards to general corrosion on steel increases with increasing temperature, oxygen content, water velocity, the content of corrosive contaminants, eroding particles, and conductivity. The seawater containing salt forms a perfect electrolyte with the ship’s hull, fully made up of iron (mild steel), to form a galvanic cell.

Galvanic cell occurs when two dissimilar are in contact with each other leads to corrosive medium (electrolyte) i.e. the more active metal undergoes corrosion and the less active metal acts as a cathode and stays protected. Like that way, people use to paint the ship hull. But it is impossible to paint often, since it can done only in dry dock condition.

So that people go for depressed current cathodic protection system with sacrificial anodes like aluminum, zinc, magnesium and GI anodes. But we should replace the anodes in very short period.

Impressed current cathodic protection with MMO Coated and Platinum plated Titanium and Niobium anodes will last longer for 15 to 20 years and reference electrode for monitoring the system.

ae6d273b-29e1-479f-b172-a5dedeecf370|0|.0|27604f05-86ad-47ef-9e05-950bb762570c

June 18, 2021 09:56 by

admin

admin

The following are some of the advantages of the ICCP system:

Impressed Cathodic Protection System has several advantages over other types of cathodic protection systems because it makes use of an external power supply to power both the anode and cathode systems, making it possible to protect any structure, regardless of its size.

When compared to other prevention methods available on the market, the use of ICCP systems has a longer life span and greater durability.

The structure's life expectancy has been extended.

The anodes are small and lightweight, making them simple to install and store.

a9db9953-b8d5-47f3-9e94-42e711390677|0|.0|27604f05-86ad-47ef-9e05-950bb762570c