December 11, 2019 17:00 by

admin

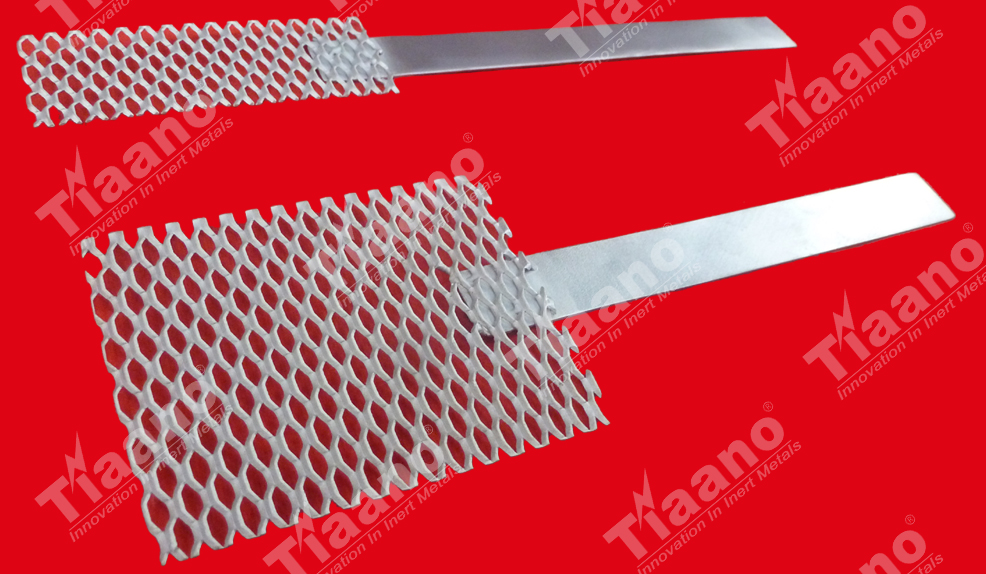

adminPLATINUM PLATED MESH for electro oxidation to treat the water

In recent years, there has been increasing interest in finding innovative solutions for the efficient removal of contaminants from water, soil and air. Government also strictly insist the industries to make a zero discharge and chemical contamination free soil and water to protect our environment.

ELECTRO OXIDATION AND ELECTRO COAGULATION process together treats the water as a disinfection using our Platinized titanium mesh.

By passing the DC current through Platinised titanium mesh leads to remove BOD COD ratio landfill leachate was conducted by means of electrochemical oxidation process. Electrochemical oxidation process is effective in removing pollutants from landfill leachate.

Depending on the effluent nature, an increase of the conductivity of the solution may be required: the value of 1000 mS/cm is commonly taken as a threshold. Salts like sodium chloride can be added to the solution, acting as electrolytes thus raising the conductivity. Typical values of salts concentration are in the range of few grams per liter, but the addition has a significant impact on power consumption and can reduce it by up to 30%.

Electro-oxidation (EO), also known as anodic oxidation, is a technique used for wastewater treatment, mainly for industrial effluent playing roll in advanced oxidation process. The most general layout comprises two electrodes, operating as anode and cathode, connected to a power source.

Electro-oxidation is an excellent and eco-friendly technique for the removal of persistent organic contaminants, electrochemical advanced oxidation processes are ordinarily used to remove COD and BOD presence in the water.

Platinum electrode provides good conductivity and they are inert and stable at high potentials. At the same time, the oxygen evolution over potential is low and comparable to that of graphite. As a result, electro-oxidation with Platinum electrodes usually provides low yield due to partial oxidation of the compounds. The contaminants are converted into stable intermediates, difficult to be broken down, thus reducing current efficiency for complete mineralization

However, this technique suffers the primary disadvantage of high energy consumption and low current efficiency.

Tiaano supplying the ELECTRO OXIDATION systems and its spares for the different regions. Also we are supplying the MMO Coated plates (titanium) instead of platinized titanium mesh to treat the water.

PLATINISED PLATED MESH

26820561-ab08-4fa7-8006-9991219aa96d|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c

November 13, 2019 12:12 by

admin

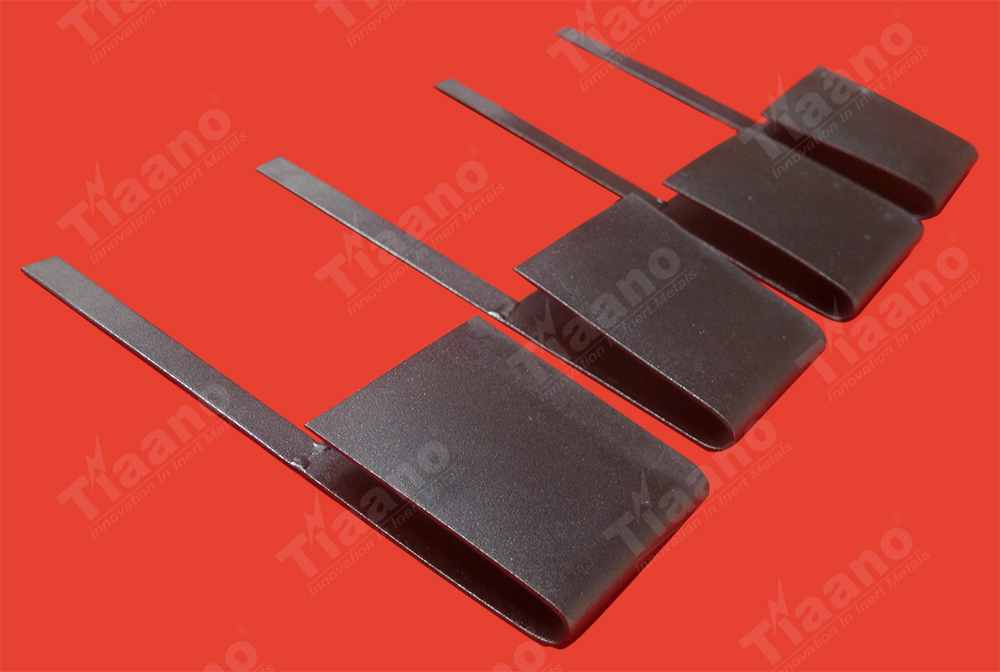

adminMMO COATED DSA PLATES for electro oxidation to treat the water

In recent years, there has been increasing interest in finding innovative solutions for the

efficient removal of contaminants from water, soil and air. Government also insist the industries to make a zero discharge and chemical contamination free to protect our environment.

ELECTRO OXIDATION AND ELECTRO COAGULATION process together treats the water as a disinfection using our MMO coated plates with the catalyst of Ruthenium Oxide (RuO2).

Treatment of a low BOD COD ratio landfill leachate was conducted by means of electro chemical oxidation process. Electrochemical oxidation process is effective in removing pollutants from landfill leachate.

Electro-oxidation (EO), also known as anodic oxidation, is a technique used for wastewater treatment, mainly for industrial effluent playing roll in advanced oxidation process. The most general layout comprises two electrodes, operating as anode and cathode, connected to a power source.

Electro-oxidation is an excellent and eco-friendly technique for the removal of persistent organic contaminants, electrochemical advanced oxidation processes are ordinarily used to remove COD and BOD presence in the water. However, this technique suffers the primary disadvantage of high energy consumption and low current efficiency.

Tiaano supplying the ELECTRO OXIDATION AND ELECTRO COAGULATION systems. Also we are supplying the MMO Coated plates (titanium) used in the system.

We, the Ti Anode Fabricators private limited, chennai supplying different types of MMO (mixed metal oxide)Coated plates for Water oxidation.

MMO Coated PLATES :

f094b22b-8f44-406f-bb7f-45724c83fafa|1|5.0|27604f05-86ad-47ef-9e05-950bb762570c